Production Technology

Flexible Incorporation of Leading-edge Technology Making Possible Reliable Supplies of High-Quality Products

For many years, Alps Alpine has been working on the automation and generalization of production processes in the midst of manufacturing a wide range of products, and has developed technologies to build in-house proprietary processes.

At the same time that we have been moving forward with the in-house development of software for production equipment, we have also been actively starting the use of our own in-house AI to improve production lines in recent years. By establishing mass production systems for a variety of products, we can flexibly respond to customer requests and raise the level of our quality, cost, and delivery (QCD)overall.

Reliable Production Supported by Automation and Process Design

Manufacturing process technology is the skill to build substantive processes to engage in the mass production of products and to manufacture and develop the robots necessary for that purpose. At Alps Alpine, we have been aiming to improve productivity and quality focusing on automation of production processes and process design from early on.

Automation is a term used to refer to the use of specialized production equipment and robots to complete multiple tasks such as processing, joining, and assembling materials in complex manufacturing processes.

One of the advantages of automation is that it makes possible the manufacture of high quality products at high speed and in large volumes.

At Alps Alpine, we are in total pursuit of robots with multiple joints and robotics for high-speed work, which are increasingly being used in a widening field of production processes. We have succeeded in improving the precision and efficiency of our manufacturing by minimizing the amount of work conducted by humans and using robots to perform the tasks. Also, since robots perform the larger part of our production processes, they also contribute to the effective utilization of our human resources.

In process design, the production division proposes ideas for products to the design division to promote efficient production, and we conduct planning for lean manufacturing processes. In accordance with that, we take on the duties of examining components and production equipment parameters, conducting the planning of manufacturing itself, and arranging system inputs for production equipment.

Currently, we are also working to widen the applicable range of work to which automation is applied to include work that is conducted by humans. These include the transport of materials and components to the production line, and the packaging and shipping of finished products.

The promotion of automation and process design leads to a reliable supply of products and further cost reductions. It is an important factor in providing ever better products that meet the needs of our customers.

The Optimization of our Production System Is Made Possible by our Production Facilities for In-house Manufacturing

The key to making progress with automation and process design is having production equipment in house. In-house production enables us to accumulate manufacturing process technology from within the company, quickly make improvements to our facilities, and makes flexible process design a possibility. In order to automate the manufacturing of a wide array of product lines ranging from various types of components to modules, it is essential to develop production methods and production facilities that are suited to each product.

Alps Alpine set to work on developing its own production equipment from an early stage, and since that time has continued to conduct updates while quickly incorporating the latest technologies and trends of the day. This attitude of independently making our own equipment has been carried on for a long time since the founding of the Company, and it has become one of our strengths.

When making use of robots, we do so on a global scale by combining the “competitive domain” of in-house produced equipment with the “cooperative domain” of effectively using commercially available robots. While raising our competitiveness by reflecting our own company know-how in key processes, we are at the same time able to shorten lead times for equipment development and production preparation.

Along with our in-house production, we are also focusing on the development and mass production of general-purpose automation equipment. We share production equipment for various product lines. For components of similar size and materials, we strive for smarter manufacturing artisanship through assigning production equipment that can be shared within the production line, which thereby improves efficiency and productivity.

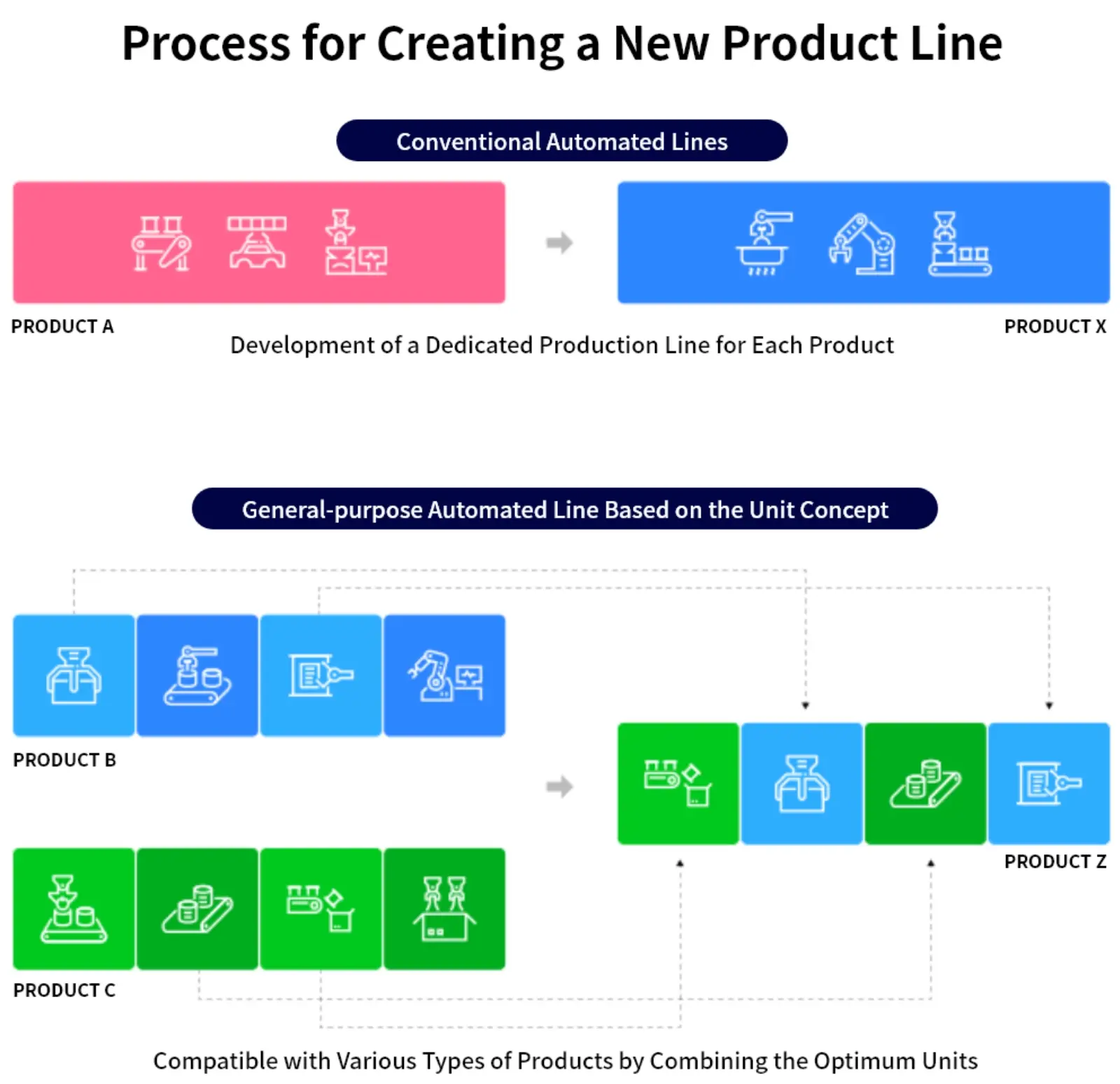

The Unit Concept is a production system that we created while in the process of generalizing production machinery. It divides the components of each automated process, such as the main process/transfer/supply stages, and combines the specialized and standardized parts used in each product. The system makes it possible to set up the optimal production line with reduced costs in a short period of time.

AI Outfit with Our Proprietary Know-how that Contributes to Further Raising QCD

Along with hardware, we are also advancing with the in-house production of software. In addition to the image processing that we have installed in robots up until now, we have also launched the use of our own AI in domains such as inspection and measurement, which conventionally have been difficult to perform without the involvement of humans. We are pursuing productivity and quality improvement by using AI to automate intricate tasks that previously could not be handled by image processing as well as to separate products that pass or do not pass quality standards, such as image judgment.

We are also working on the smart factory concept by collecting all kinds of production-related data from our facilities, and the results of our analyses are leading to improvements in productivity.

We are focused on developing the human resources who will carry the next generation, and moving ahead with training based on the assumption that they will be using AI technology and software. We have created a curriculum that incorporates not only basic theory, but also our proprietary know-how and a wealth of concrete examples. By flexibly reflecting such training in our human resource development, we are developing professionals in automation and process design.

Through the pursuit of automation and generalization as well as the use of AI, Alps Alpine has created a system that enables the reliable production of products. In response to our ever-changing society and the era, we deliver high precision manufacturing artisanship built on the foundation of our accumulated know-how and new technologies. This is what Alps Alpine’s manufacturing process technology has to offer.