Thermal Transfer Printing Technology

Igniting the Potential of Printing

Thermal transfer printing technology supports modern lifestyles from all sides. Alps Alpine has developed thermal transfer printing technology, a printing technique that uses heat to enable printing on a wide range of surfaces, regardless of whether they are three dimensional or flat.

Thermal transfer printing technology enables high precision, detailed printing on any object

Thermal transfer printing technology differs from the coating method, in which ink is directly sprayed onto the object. Instead, the desired image is painted on a film beforehand, and that film is then affixed to the object and transferred to it. This technique allows for a printing in a rich array of designs.

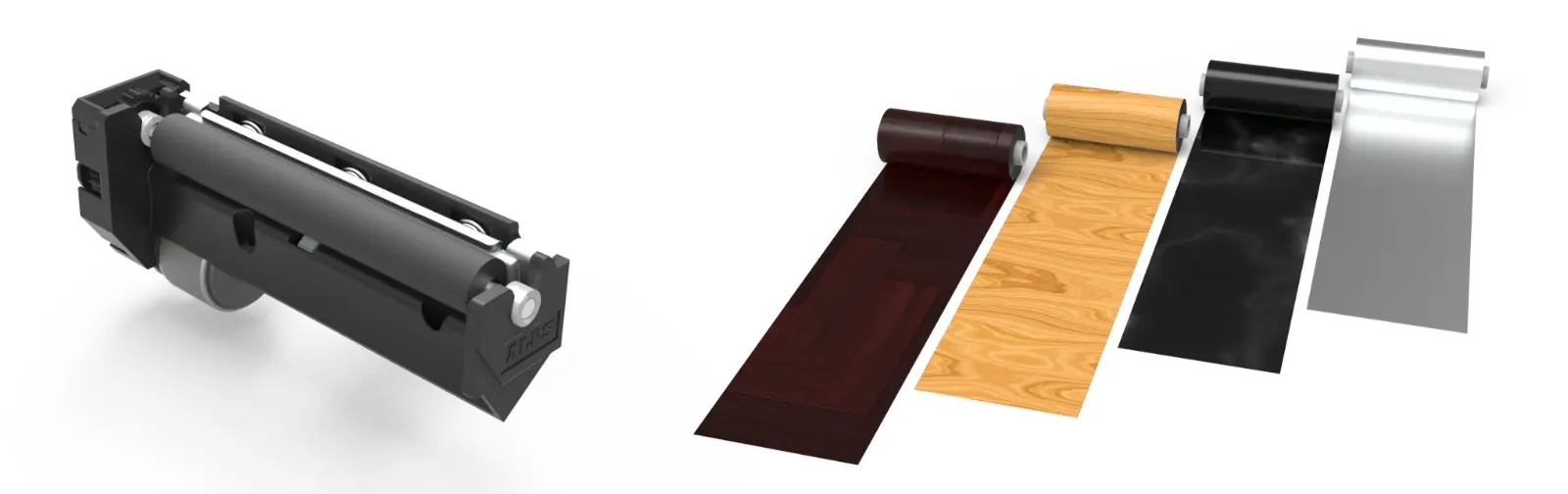

Thermal transfer printer / film with printed images

Smartphones, consumer electronics, miscellaneous goods, the interiors of vehicles, and more—products featuring printing by thermal transfer printing technology are integrated into our everyday lives.

Thermal transfer printing technology involves techniques such as “hot stamping,” in which a heated roller is pressed against an object, and “in-mold / laminate molding,” in which a printed film is directly inserted into a metal mold and is integrally molded. It makes possible a variety of decorative print designs on any object.

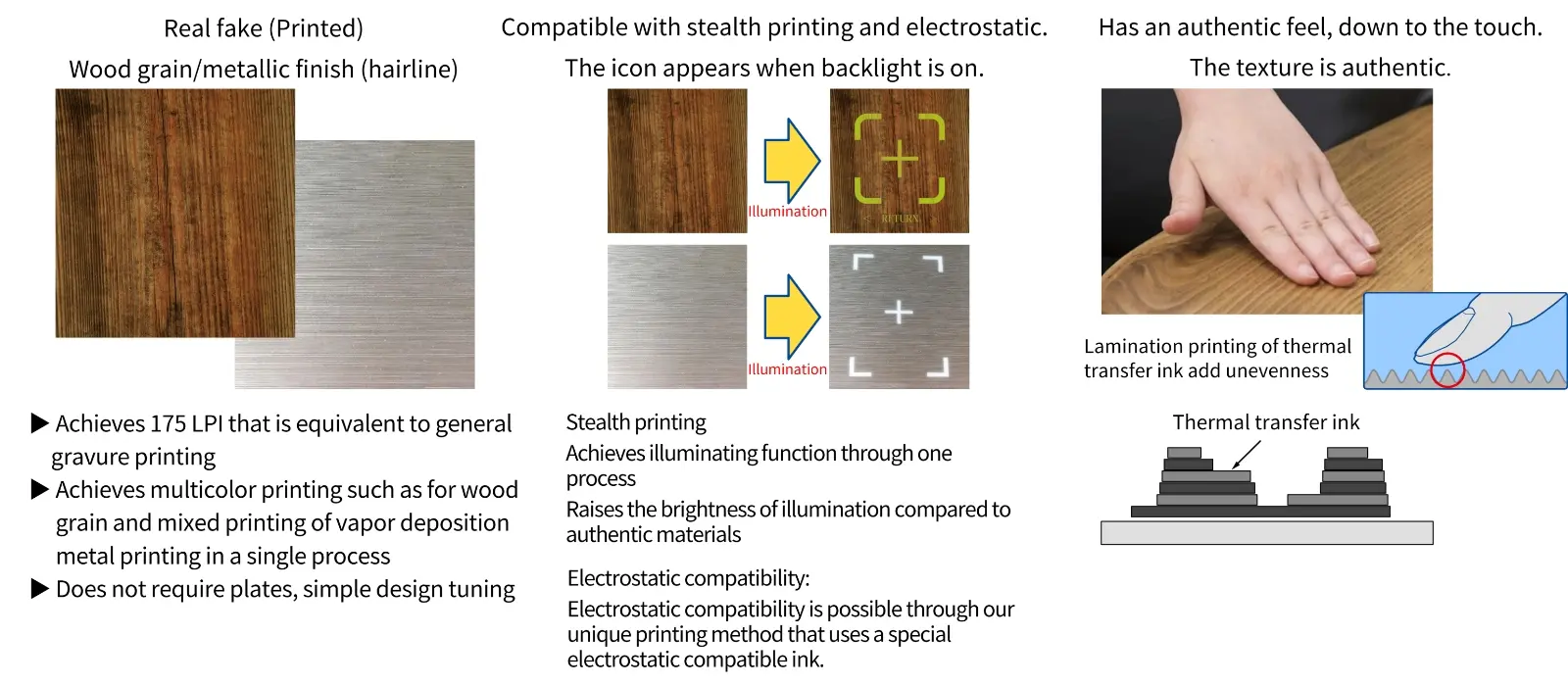

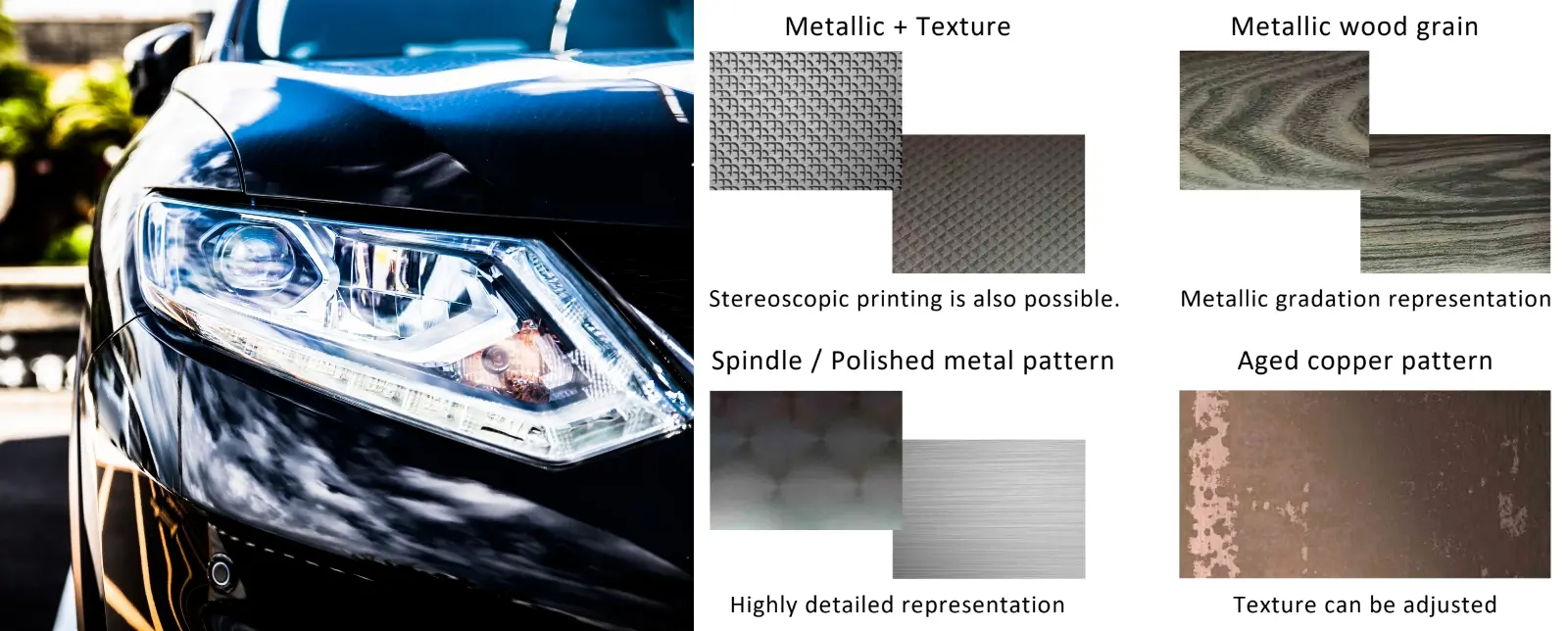

The films that we use make effective use of their high resolution and high-definition characteristics to make possible printing that would be difficult with the coating method. Various designs and textures can be created, such as coloring with gradients, defining fine lines, and reproducing realistic metallic textures.

Films with prints expressing various textures

Alps Alpine’s thermal transfer printing technology leads the way to the future

The history of thermal transfer printing technology at Alps Alpine began in 1974, when we developed the first micro-printer. It was followed by the creation of a great many products, such as word processors, printers for making CD labels, business card printers, and more. These more than 50 years of experience form the foundation on which we are developing our printers.

Alps Alpine printers are also used in our in-house development of hardware and software. In regards to hardware, we manufacture our own high precision, low energy consumption thermal heads, compact module gears that accurately feed printed materials, and rollers engraved with minute protrusions within several tens of microns. We have endeavored tirelessly to raise the performance of our company’s printers.

Regarding software, all of the software that is used in the printing process is developed and operated by Alps Alpine, ranging from color matching to coordinate tones on to image processing. Furthermore, we confirm and analyze various factors related to printing on the actual machines, such as flow rate analysis, head pressure, and flexible print target transport. We use the information that we accumulate in the development of new products, and this leads to further improvements in product performance.

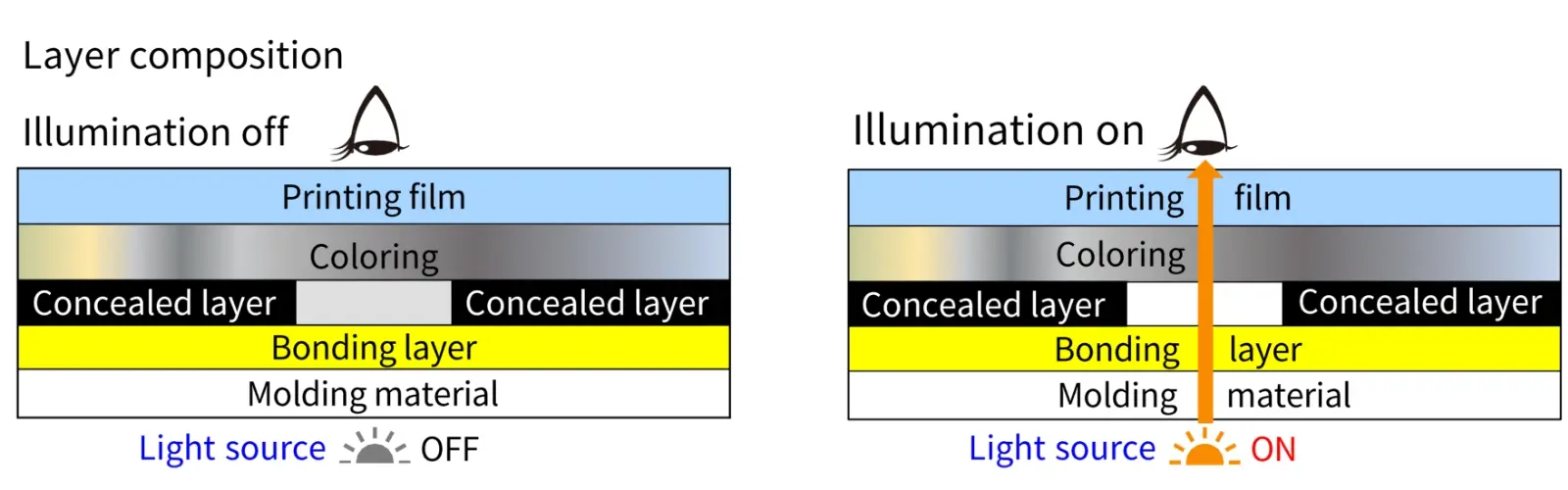

Further, Alps Alpine has developed a proprietary thermal transfer decorative printing technique by fusing its static technology with thermal transfer printing technology. Combining this with our unique printing method—in which we use a special ink that makes text and designs stand out when light shines on the print—we have created printed surfaces that make operable designs spring to life on flat surfaces that only appear to have wood grain or a metallic finish.

This decorative printing configuration can be used for purposes such as printing the operation screen directly on the wood grain interior of an automobile, and it will appear only when in use, for example. It makes possible the interior of the future, in which a limited amount of space can be used effectively.

Obtaining a large share in the home use sector, reducing environmental burden

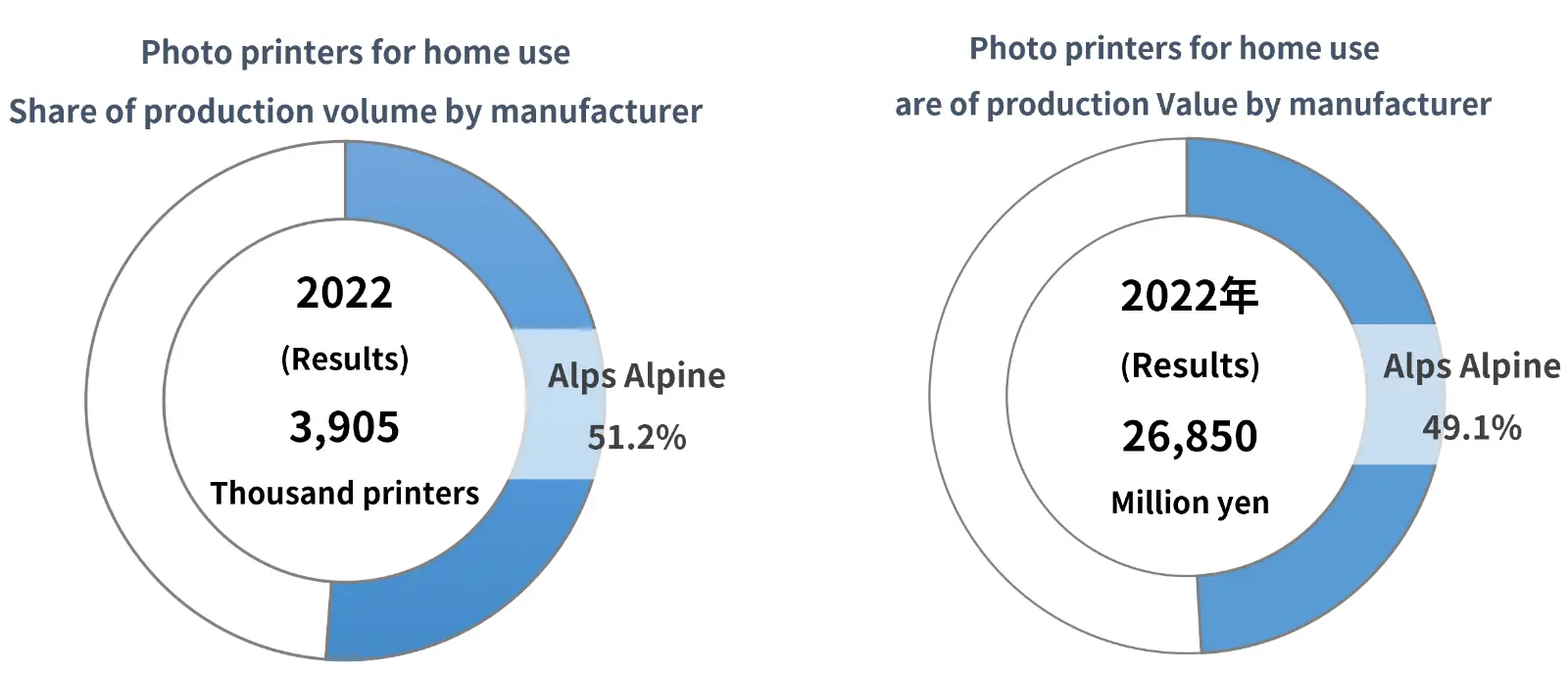

Note: From 2023 Full Details of the Printer Market, Chunichisha Co., Ltd.

Through accumulating this technology, we obtained a 51.2% share of production volume by manufacturer in the market for photo printers for home use in 2022. In addition, we are also involved in conducting the manufacture and sales of industrial printers as well as sales of films for print use, and have obtained a large share of the market in the industrial field.

And at the same time that Alps Alpine is building its market share, the company is also focusing on reducing its environmental load through the use of thermal transfer printing technology. For example, we have replaced the plating process, which generates toxic substances, with the use of films with highly reflective, metallic prints, thereby achieving reductions in costs and environmental impact. This technology is finding practical applications in the headlights of automobiles. By applying metallic printing directly on the transparent area, we can reduce costs and make the manufacturing process simpler, and at the same time reduce our environmental load.

Alps Alpine has fine-tuned its thermal transfer printing technology over more than 50 years. We use it on a diverse range of applications, from everyday purposes to industrial applications such as on the interiors and exteriors of automobiles. Going forward, we will continue pushing the leading edge of technology for printing, while placing importance on environmental considerations and incorporating new technologies from other fields.