Precision Machining Technology

Beautiful Products Come from Good Components, and Good Components Come from Good Molds. Precision Machining Technology Supports Alps Alpine’s Manufacturing Craftmanship.

In the manufacturing industry, precision processing technology to handle molds is indispensable. Molds make it possible to mass produce components of the same shape in such ways as pouring and hardening resin, and by cutting out and bending metal sheets to make the same shape. It is no exaggeration to say that they are the cornerstone of the manufacturing industry.

Light, thin, short, and small products have become the trend in recent years. Accordingly, the technical standards required of molds have been increasingly rising in order to manufacture such thin and small products with high precision.

In order to establish stable production of items with high quality, Alps Alpine has viewed the manufacture of precision molds in-house as being indispensable, and has been building an integrated system that includes the manufacturing of molds ever since our establishment in 1948.

Contributing to the creation of beautiful products by bringing together the best precision machining technologies

“Beautiful products come from good components, and good components come from good molds.” This phrase has been handed down since the establishment of Alps Alpine, and was born from our unchanging philosophy that molds are responsible for the precision of products. We are taking on the development of new products by applying the unique know-how that we have built in-house to molds—the foundation of precision machining.

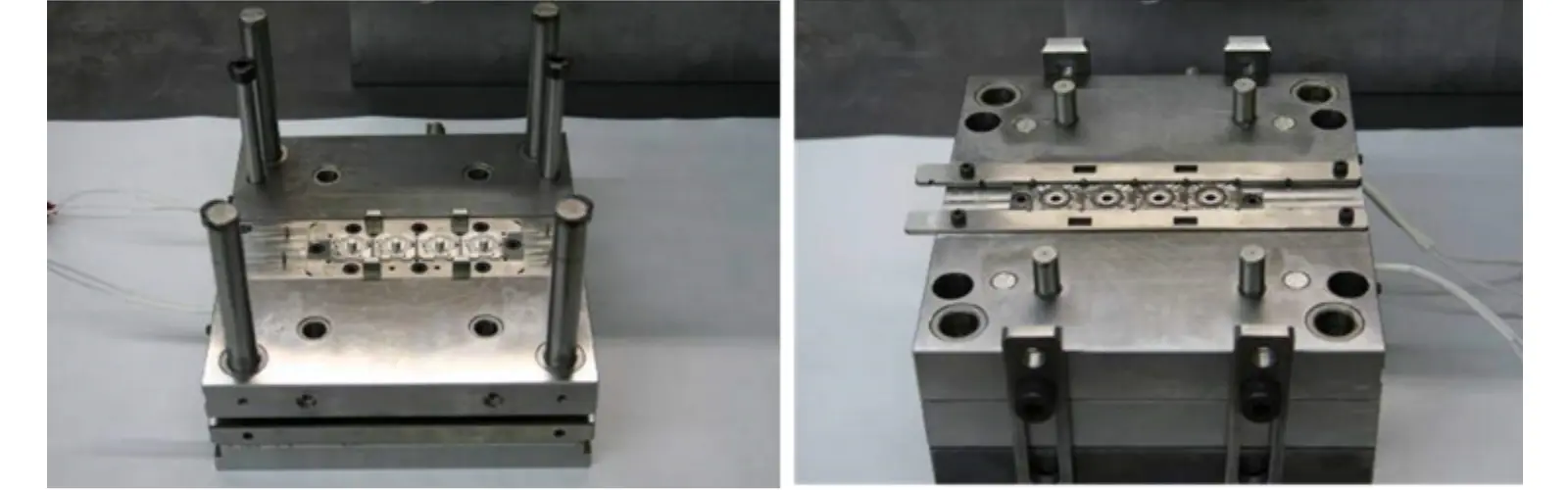

Currently, Alps Alpine conducts the in-house development of a total of four types of molds.

Our plastic molds create shapes with resin that is injected inside, and our press molds cut and bend metal materials inserted into them. Also, we have insert molds that integrate and shape components made of different materials such as metal and plastic, and molds that form shapes from rubber materials.

Using these molds, it is possible to mass produce components of the same shape in a short period of time and to supply products in high volume lots of several million units per month.

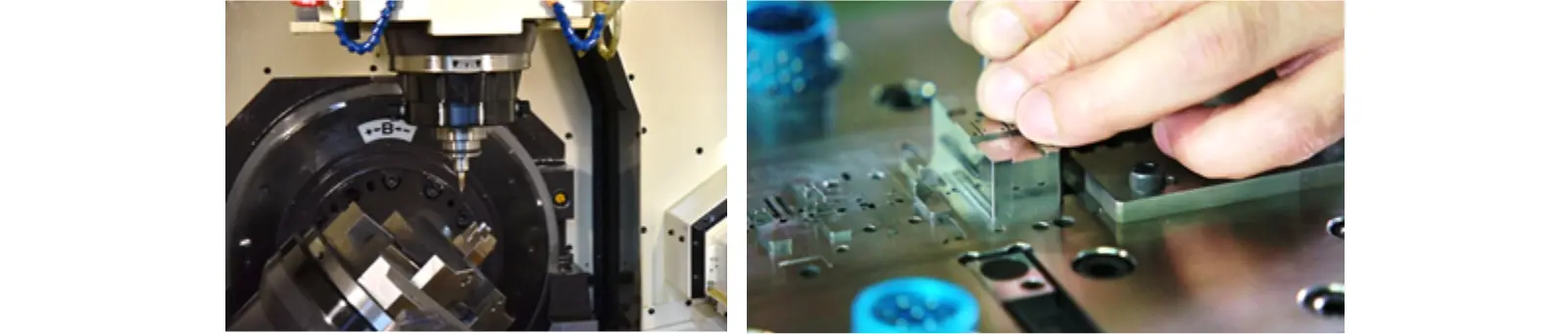

A noteworthy features of mold development at Alps Alpine is our system which leverages precision processing technology to give form to creative ideas generated inside the company in order to create novel products.

Precision molds that respond to the need for small, light, short and thin products

Many of the components that Alps Alpine manufactures are used in small, thin products found in smartphones and other consumer devices. Moreover, minimization of the components used to make smaller devices with higher performance is continuing to progress.

The molds used to give shape to these components are also extremely small, so injecting the resin into them is not an easy procedure. Alps Alpine’s precision processing technology makes it possible to inject resin into spaces thinner than a human hair and mass produce components that meet strict dimensional tolerances. Also, metal presses can process metal plates to the same thinness as a gold leaf. We apply metal molds that use presses to the cutting and bending of metal sheets, which allows us to consistently produce ultra-thin components without any deviations.

Initiatives Aimed at Training Engineers, Further Evolving Technology

In taking on new challenges, we have created an in-house environment in which the engineers who will carry the next generation are taking the lead in development, and we are emphasizing training for our engineers. In addition to the nationally set trade skills test, we are conducting an in-house skill testing system as a measure for developing human resources in the molding division.

To process products and ensure the provision of a stable supply of mass-produced products from a long-term perspective, it is important that we ceaselessly evolve the mold technology that we have developed within the company. This unchanging idea is nothing short of the driving force that supports the maintenance of quality and stable mass production while giving us the edge of superiority. Going forward, Alps Alpine will continue endeavoring to raise our manufacturing craftsmanship, develop human resources, and remain fully committed to our belief that “beautiful products come from good components, and good components come from good molds.”