Optics Technology

Projecting the Future: Optics Technology with World-class Precision and Performance

Alps Alpine’s optics technology has been providing solutions in a wide range of fields, including optical communications, consumer devices, industrial devices, and automotive applications.

We have developed lenses for reading and writing data on CDs, camera lenses for cell phones, optical communications, measuring instruments, laser processing equipment, in-vehicle equipment, and many other applications. The know-how we have accumulated over the years has led to the creation of next-generation interfaces.

More than 30 years of history with glass lenses

Alps Alpine started its engagement with optics technology in the 1980s, with the development of lenses for reading CDs. These highly precise yet small sized lenses were indispensable to reading and recording data using lasers. The development of these lenses became the foundation of Alps Alpine’s optics technology, which later evolved into aspherical lenses used for communication, and has continued to progress for more than 30 years.

Lens for reading a CD drive

Since the beginning of our optics technology development, we have focused on glass lenses, which are made by heating glass to high temperatures to soften it, and then shaping it using precision molds. Glass lenses are superior to plastic lenses in terms of heat resistance and weather resistance.

The high reliability of glass lenses is aptly demonstrated in lenses for use in optical communications, which have become a core product of Alps Alpine’s optical technology. Alps Alpine started mass production of lenses for use in optics communication around the year 2000—when optical communications for use with the Internet began to spread—by applying the lens development technology amassed by our audio business. We have developed glass lenses that are required to function even in harsh environments. For example, our lenses are incorporated into optical communication cables that are laid on the ocean floor and serve as the foundation for long-distance communications.

Currently, the diameter of the lenses manufactured by Alps Alpine for optical communication use is approximately 1 mm. We have succeeded in mass producing extremely small sized, high precision lenses, and we hold the top share in the global market for aspherical glass lenses for optical communication use, at approximately 30%.

Lens for use in optical communications

Core technology that achieves unevenness in surfaces down to the single nano level

Precision mold processing is one of the core technologies that Alps Alpine has created in order to manufacture extremely small lenses. All of our glass lenses are shaped through using molds, and are manufactured in-house using extremely detailed molds that directly affect the precision of the lenses.

By using molds designed and manufactured on a nanometer scale without performing the polishing process necessitated by general lens manufacturing, we create lenses that have achieved the highest value of aspherical surface shape error at 0.15μm or less, and surface roughness of 5nm or less. The molds achieve high precision while simultaneously shortening the amount of time required for molding, retaining the capacity to manufacture 100 units in approximately one minute.

In the lens design stage, optical simulations are conducted to avoid phenomena that impact lens performance. These include such issues as wavefront aberration, in which light is not focused on a single point and appears blurred, as well as chromatic aberration, in which the focus position and image sharpness are affected by the color of the light. We have developed an achromatic lens that corrects chromatic aberration by joining together lenses with different refractive indices, and a FAC lens that can adjust light to a parallel state only on the side of the oscillating direction (lower refractive index) where the laser moves quickly.

LiDAR represents an example of the use of a FAC lens. In automated driving technology, these devices measure the distance to an object and the shape of the object based on information they obtain from the reflected light of a laser beam. In addition, FAC lenses are used across a wide range of applications, such as lenses used for HUDs—which display information in the human field of vision by superimposing it on the surrounding scene so that it blends in—and laser processing equipment used in metalworking.

Also, we manufacture lens arrays as an applied product, which are made by an arrangement of many microscopic lenses with spherical surfaces. We also conduct direct molding, in which metal holders are attached at the same time as molding. In these ways, we meet needs in the optical communications domain, and also in various fields such as industrial machinery and in-vehicle applications.

Creating the Interface of the Future with our “Mid-Air Display”

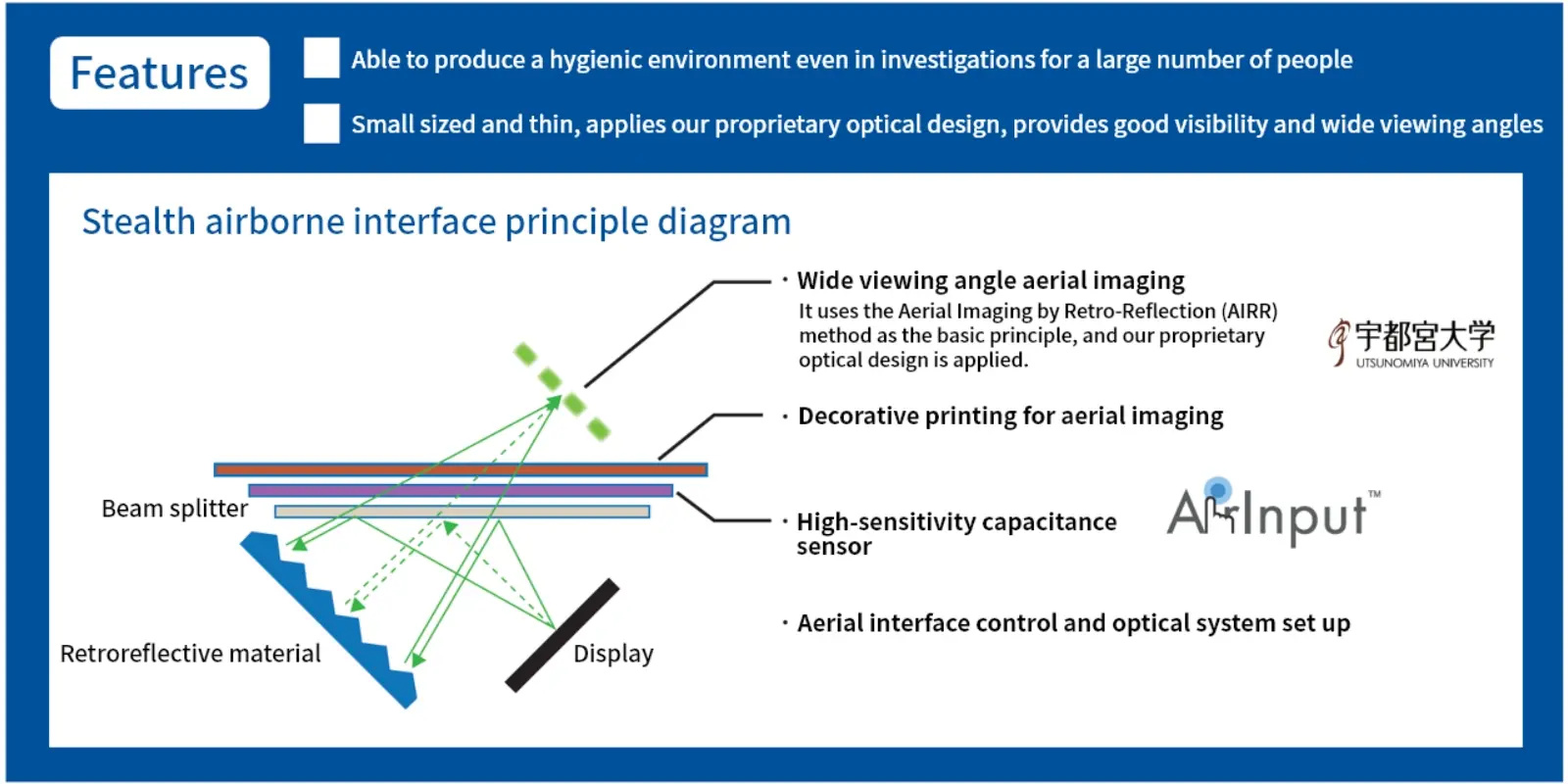

The Stealth Aerial Interface was inspired by the demand for non-contact operations, and developed based on the know-how related to optics technology that we have accumulated to date. This device is the first in the world to make possible an “operable aerial display,” and has won the runner-up Grand Prix in the Key Technology Category of the 2022 CEATEC AWARD, which recognizes leading-edge technologies from Japan and abroad. Instead of eliminating all mechanical controls such as switches and buttons, it has a function that allows the display to come up by gesture only when it is necessary. This is made possible by employing light source control technology developed for lenses used to read and record data using lasers.

In addition, the Stealth Aerial Interface also utilizes electrostatic technology and thermal transfer decorative technology. This next-generation interface has been created by combining each of Alps Alpine’s core technologies.

We forecast that the stealth aerial interface will find applications in medical settings where it is necessary to manage hygiene and in construction sites where operations must be performed in unclean conditions. If the functionality of the aerial display is expanded in the future, it is expected to find applications in spaces such as general households and commercial facilities. In the not-too-distant future, we may see aerial displays used in such settings as tables and walls where remote controls and switches are concentrated, in elevators used by large numbers of people, and in cash registers used for checkout in stores.

Alps Alpine’s optics technology has specialized in glass lenses for over 30 years. Going forward, in addition to continuing with the development of high-precision, highly reliable lenses, we will find new possibilities in the optics field.