Contacts & Resistors Technology

Continuing to improve since our founding The Origin of Alps Alpine

When handling various devices, there will be a switch and volume control. The switch used to turn it on or off with is likely to be contact technology, while the volume switch turned left and right to adjust the output uses resistor technology.

It is no exaggeration to say that these contacts and resistors are used in nearly all electronic devices. Alps Alpine is dedicated to creating technology that enhances the connections between not only people and machines but also between machines themselves.

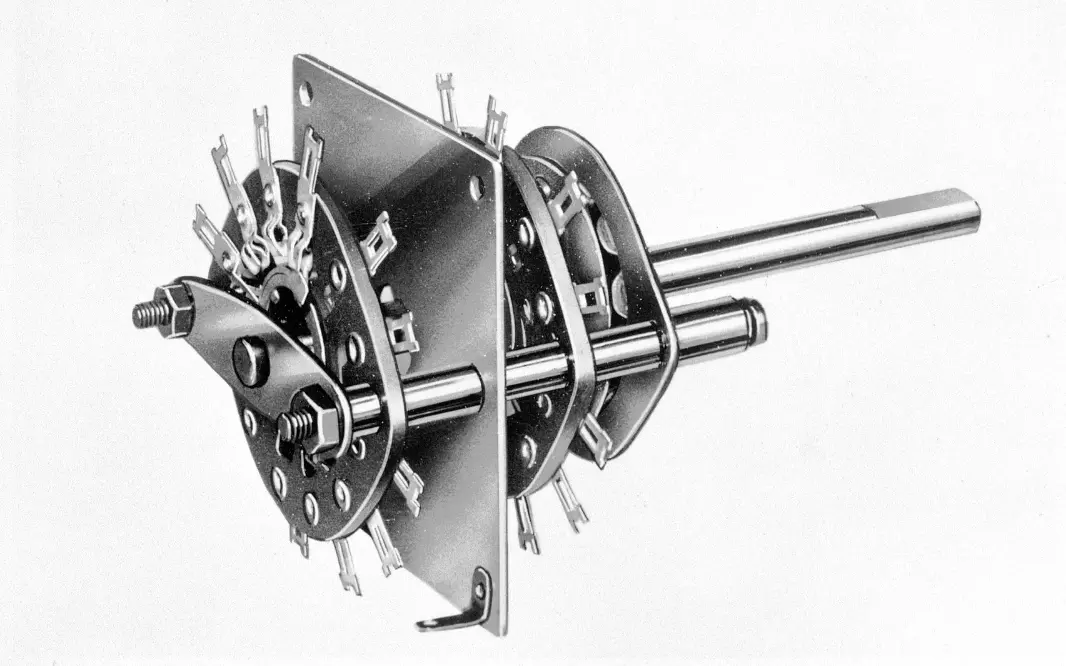

Getting our start with the development of the rotary switch in 1948

The former Alps Electric started out with the mass production of rotary switches. From this type of switch, which rotates contact points to bring an electric current to a circuit, we branched out into resistor materials, which we have since developed into the resistor technology that we continue to deal with to this day.

Rotary Switch

The transistor technology that we work with does not involve a fixed resistor named with a fixed resistance value. Rather, it is at its core a variable resistor that can change its resistance values due to its movable point of contact.

Our contact and resistor technologies were created to serve as essential components in cassette players and VCRs in the 1970’s and 1980’s. Now, they are finding applications in sensors that are installed in automobiles and miniaturized electronic devices. Alps Alpine’s point of contact and resistor technology is used in the components of numerous devices today, ranging from video game controllers to smartphones.

An exacting focus on long operating lives and feeling

At Alps Alpine, we have worked to build up a collection of technologies since our founding. We have not only worked on product development and expansion, but we have also maintained an exacting focus on long operating lives. A switch is a component that must be able to easily bear a load as it will be operated a great many times. Even on the inside, the sliding points of contact that allow it to switch on and off can’t avoid wearing out from friction along with everything else. To prevent wear and tear, lubricants like grease can be used, but this presents a problem in that grease is not conductive to electricity. Since points of contact that have grease on them become unstable, there must be a balance between wear resistance and electrical conductivity in order to increase the length of the useful life of the sliding points of contact.

Alps Alpine, with our many years of technological know-how, have developed a formula for a grease with the optimum balance. We use our original formula of contact grease on all of the switches that are manufactured by Alps Alpine, and thereby we have succeeded in improving the contact stability which in turn extends the useful lives of our switches.

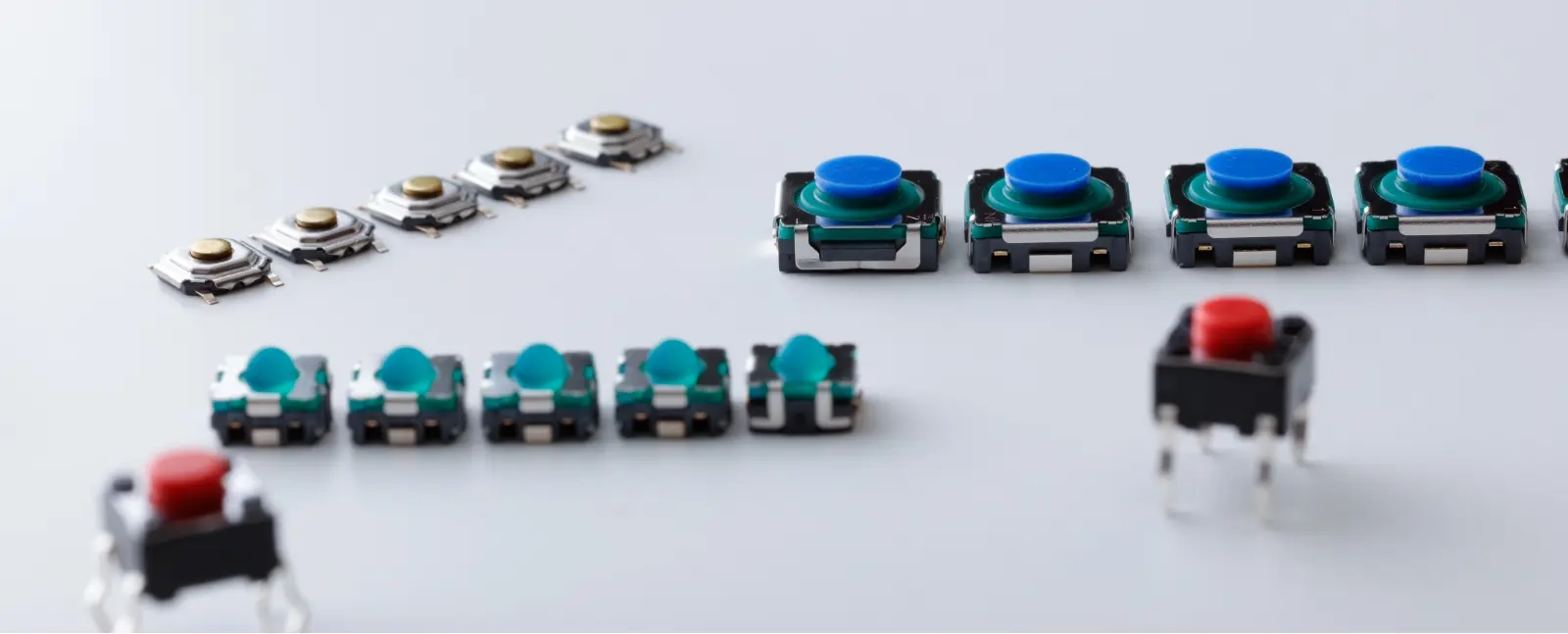

An important feature of the TACT Switch™ that was developed by Alps Alpine is how they feel when they are pushed. For that reason, we have developed switches that employ a combination of springs and rubber that we use to provide weight and tactile clicking sensations. In the last few years in particular, we have been continuing to research and improve the way our switches feel when operating them, basing our work on human factor engineering. Alps Alpine is responding to different kinds of usage and essential applications by selling 100 series of switches currently, including the TACT Switch™, and switches from each series are finding applications in over 1,000 products. Our annual production is reaching approximately five billion units, which is calculated to be approximately 160 units per second. The cumulative production of our tact switches is expected to be more than 155 billion units by 2023. We are proud to be among the top class of switch manufacturers in the world, with our switches being used by many customers and in a great deal of products.

Expanding the Range of our Automobile Switches from human to machine interface (HMI) to machine to machine interface (MMI)

Recently we have developed a diverse variety of interfaces with our touch panels that use our electrostatic capacitors. While those are being installed, switches and volume knobs made from our contact and resistor technology are in a wide variety of devices because of their superb reliability.

Currently, needs are continuing to grow in the field of in-vehicle equipment. An example of an HMI interface that connects people to machines can be found in the switches in automobiles that allow people to open and close the windows. However, as cars become more high-tech in this automated day and age, more MMIs that allow the machines themselves to coordinate are being installed in automobiles.

Self-functioning switches are becoming essential components in today’s automobiles, and they are operated by output which is determined by sensors, in particular door locks, but also including the detection of motor operation and automatic driving. Beyond the conventional switches operated by humans, contact and resistor technologies are expanding the limits of their connections with on-board computers and their ability to increase the smooth operation of these systems.

Unlike HMI, which is installed in many vehicle interiors, MMI differs in that it finds applications in more severe environments, such as in and around doors on the vehicle's exterior and in detecting mechanical drive unit operation. To design a switch with excellent resistance against vibration and waterproofing to cope with such an environment, we were quick to develop a double-sided sliding structure, in which the movable contact makes a connection with both sides of a fixed contact. Overcoming the weakness of ordinary sliding contacts that hold contacts on only one side, the clip-shaped movable contact constantly clamps the fixed contact, making it not only stable against vibration but also resistant to dust and other contaminants.

This double-sided sliding switch is used in many automobiles and has become the standard switch for this application.

The strengths of the products that employ our contact and resistor technology is that while their design is simple, they are resistant to outside influences, are low in cost, and durable. And Alps Alpine has continued to improve its contact and resistor technology for over 70 years.

The contact and resistor technologies that support the base of our operations will continue to evolve going forward to better suit the needs of the future.