ASIC Design Technology

From Smartphones to Automotive Applications: ASIC Design Unlocks Future Possibilities for Diverse Needs

Application-specific integrated circuits (ASICs) are designed for particular uses with the aim of reducing costs and optimizing performance. Drawing on years of experience in manufacturing various sensors in-house, Alps Alpine delivers high-quality ASICs. We engage in ASIC design across a broad spectrum of industries, from consumer electronics such as smartphones to cutting-edge automotive technologies.

What is an ASIC?

ASICs differ from general-purpose integrated circuits (ICs), such as microcontrollers, in that they’re designed for specific applications. While general-purpose ICs excel in versatility, they often include features that are unnecessary for certain uses. In contrast, ASICs are tailored to particular applications, incorporating only essential functions, making them more cost-effective. Additionally, ASICs offer performance advantages, such as the ability to optimize power supply voltage and operating temperature ranges for their intended use.

Alps Alpine's ASIC Design Technology: Over Two Decades of Expertise

Alps Alpine has been designing ASICs for its modules developed in-house for approximately two decades. We specialize in integrating sensor devices and ASICs into single packages. Since launching our humidity and atmospheric pressure sensors in 2006, we’ve developed and supplied over 20 types of sensors, including geomagnetic and capacitive sensors.

Alps Alpine operates as a fabless company for ASIC development, without owning manufacturing facilities. However, we offer a comprehensive full turnkey service that covers everything from system design to quality assurance, testing processes, and post-production failure analysis. This integrated approach allows us to achieve rapid development cycles.

We've forged strategic partnerships with world-leading semiconductor foundries and outsourced semiconductor assembly and test providers that specialize in semiconductor packaging.

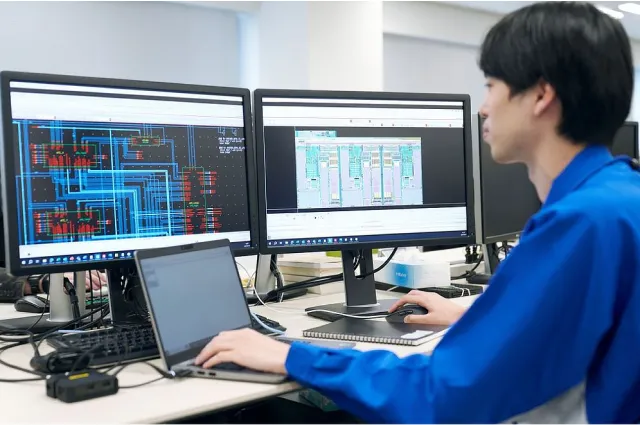

For our ASIC design process, we leverage cutting-edge electronic design automation tools that are at the forefront of the industry. We aim to optimize our design processes, enhancing both efficiency and quality in our ASIC development.

ASIC Design: A Track Record of Over 3 Billion Units Shipped

By 2023, Alps Alpine's ASIC production reached a cumulative milestone of 200,000 wafers and 3 billion chips shipped. One of our key strengths is our expertise in giant magnetoresistance (GMR) effect technology. Leveraging this specialized knowledge, honed over many years, we develop and deliver distinctive products to the market.

We've supplied over 2.5 billion geomagnetic sensors for smartphones alongside our humidity/atmospheric pressure sensor and current sensor offerings. Additionally, we've concentrated on developing capacitive sensors, which are widely used in PC touchpads.

Moreover, Alps Alpine has a proven track record in developing automotive-grade current and capacitive sensors. We meet the exacting standards of automobile manufacturers by creating products that comply with both AEC-Q100 Grade 0—the most stringent temperature requirement for automotive IC reliability testing—and the ISO 26262 functional safety standard.

| Our Products | Application | Type |

|---|---|---|

| Temperature/Atmospheric pressure sensor | Home appliances, Mobile | Mixed signal |

| Geomagnetic sensor | Smartphone | Mixed signal |

| Current sensor | Automotive | Analog |

| Magnetic sensor, Switch, Encoder | PC, Automotive | Analog |

| Capacitive sensor | PC, Automotive | Mixed signal, SoC |

| Motor current ripple signal detection | Automotive | Analog |

Streamlined Development-to-Production Workflow

Alps Alpine's full turnkey service employs a nine-step development process, enabling us to deliver flexible and rapid solutions tailored to our customers' needs:

- 1Requirements Specification Review

-

- We carefully listen to and document our customers' requirements

- 2ASIC Specification Development

-

- Through system analysis, we assess feasibility and potential risks before drafting the ASIC specifications

- We investigate FAB process and package to estimate development timeframes, costs, and mass production unit prices

- 3Development Plan Proposal and Kick-Off

-

- We present our studied development plan, which details specifications, schedules, development costs, and mass production unit price

- Upon your approval of the plan, we initiate the development process

- 4ASIC Design

-

- We perform circuit design, layout design, and then review the verification and the simulation results

- 5Engineering Sample Manufacturing and Evaluation

-

- We produce and evaluate engineering samples (ES) and then review the evaluation results

- 6ASIC Design Refinement

-

- Once the ES evaluation is approved, we prepare masks for mass production

- We develop a comprehensive test program for ASIC mass production

- 7Commercial Sample Fabrication and Reliability Evaluation

-

- Using the mass production masks, we manufacture commercial samples (CS) and conduct rigorous testing and reliability assessments

- 8Development Completion

-

- The development phase concludes upon approval of the CS evaluation results

- 9ASIC Mass Production

-

- We establish the mass production testing process with our contracted testing partners

- We oversee each manufacturing contractor, manage production instructions, monitor production status, and ensure quality control

Alps Alpine prides itself on its flexibility and responsiveness to customer requirements. Based on our extensive development experience, we've established a system that allows us to swiftly adapt to changing demands. We excel at understanding user needs and proposing realistic, optimal specifications. This expertise enables us to support ASIC development for a diverse clientele with varying backgrounds and requirements.

We employ concurrent engineering techniques, advancing multiple processes simultaneously to expedite development. This approach allows us to begin ASIC design before finalizing specifications, significantly reducing the overall development time. To meet the stringent time constraints in the consumer products sector, we flexibly adjust our CS manufacturing process—prototypes equivalent to mass-produced units. This adaptability enables us to accommodate short-term development projects effectively.

Alps Alpine's ASIC Design Portfolio (Block Diagram)

At Alps Alpine, we've designed ASICs for over 20 types of sensors, including geomagnetic and current sensors utilizing GMR elements. Here, we highlight our most widely shipped ASIC designs.

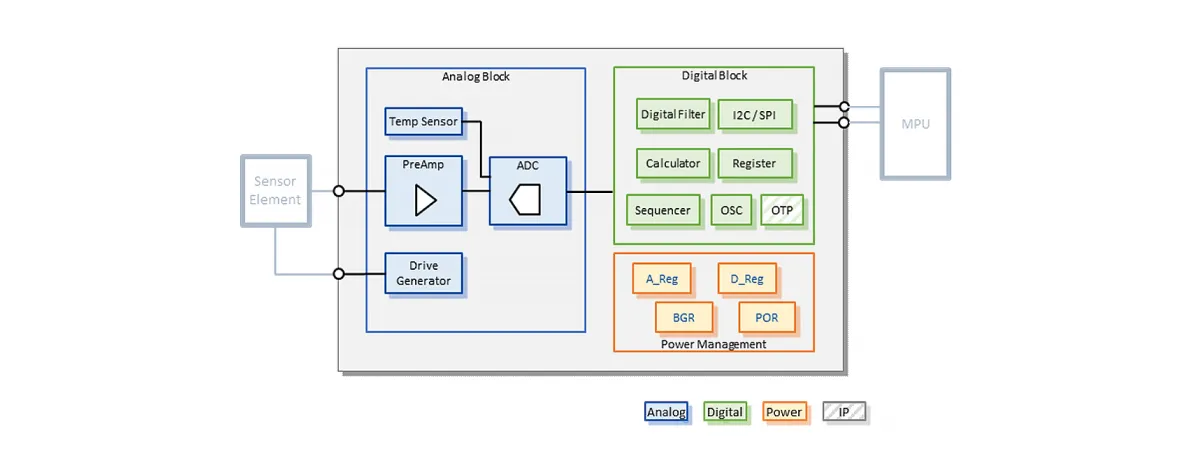

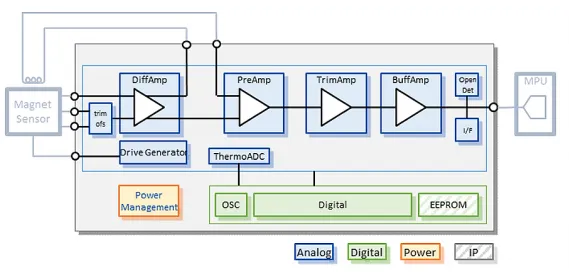

Humidity, Atmospheric Pressure, and Geomagnetic Sensor Signal Conditioning ICs (Mixed Signal)

Humidity, atmospheric pressure, and geomagnetic sensors, all leveraging GMR elements, are key products in Alps Alpine's portfolio. Our geomagnetic sensors boast extensive production records, while our humidity and atmospheric pressure sensors find widespread use in consumer applications, from home appliances to mobile devices. ASICs designed for these sensors perform critical functions; they amplify and correct analog signals from external sensor outputs, convert these signals into digital format, and then output the processed data.

- Key Features:

-

- Sensor element activation

- Amplification of sensor output signals

- Analog-to-digital conversion

- Essential calculations and compensation processing for sensor products

- Output functionality compatible with various interfaces (I2C/serial peripheral interface [SPI]) and memory systems

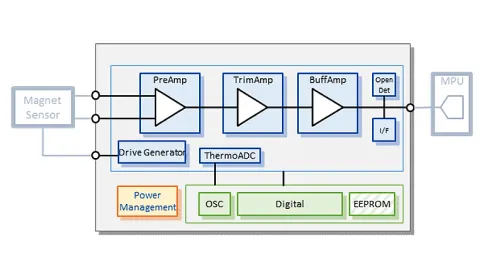

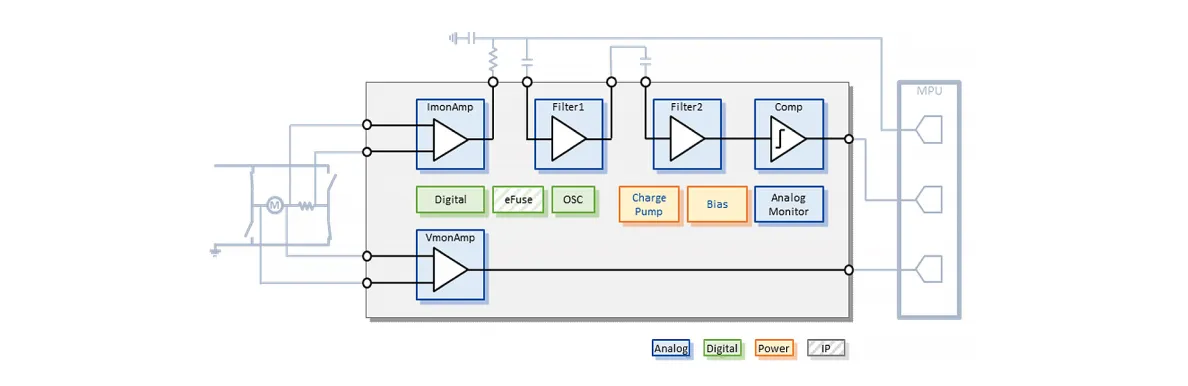

Current Sensor (Magnetic Proportional/Balanced) Signal Conditioning IC (Analog)

Current sensors are primarily utilized in automotive inverters and battery management systems. We specialize in two types of current sensors, magnetic proportional and magnetic balanced, producing custom-developed ASICs for each. ASICs for current sensors amplify and correct the sensor's analog output and transmit it as an analog signal.

- Key Features:

-

- Sensor element activation

- Amplification of sensor output signals

- Compensation for sensor temperature characteristics

- Output clamping and fail-safe functionality (compliant with functional safety standards)

- AEC-Q100 Grade 0 compliance

DC Motor Current/Voltage Detection and Current Ripple Signal Detection IC (Analog)

This ASIC is designed to detect voltage and current ripple signals in automotive motors. It monitors motor operations by sensing voltage and current. A key feature is its ability to function within a simple, sensorless system configuration while offering an impressive input range of −10 to +60V.

- Key Features:

-

- Output of inter-motor terminal voltage

- Pulse output of ripple current

- Compatibility with universal asynchronous receiver/transmitter (UART) and single-wire serial communication interface

- AEC-Q100 Grade 1 compliance

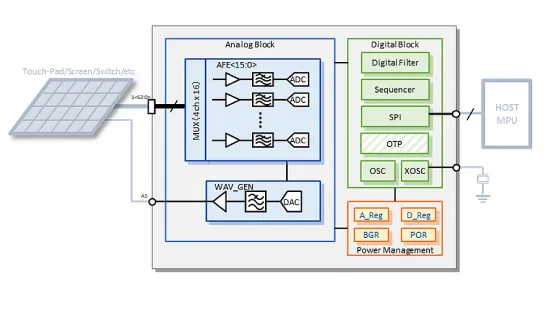

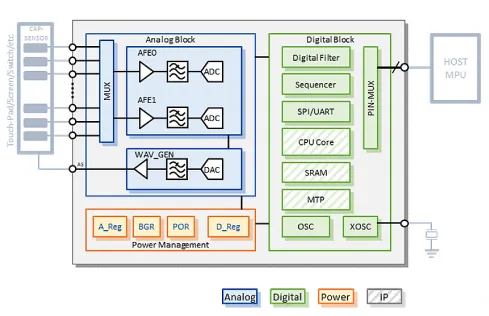

Capacitive Sensor IC (Mixed-Signal Analog Front-End/System on Chip)

Capacitive sensors, primarily used in PC touchpads, are among Alps Alpine's flagship products, alongside our humidity, atmospheric pressure, and geomagnetic sensors. We've developed two types of ASICs for capacitive sensors. The first is our analog front-end (AFE)-ICs, which acquire sensor information from touch panels and touchpads, enabling high-speed operations across multiple channels. The second is our system on chip (SoC)-ICs, which feature an integrated microcontroller, functioning as a complete capacitive sensor on a single chip.

- Key Features:

-

- Analog-to-digital conversion

- Support for SPI and UART interfaces

- AEC-Q100 Grade 2 compliance (SoC-IC)

In-House Testing and Failure Analysis Capabilities Enable Rapid Defect Resolution

Maintaining product quality requires a robust in-house quality assurance system. At Alps Alpine, we've established such a system by developing our own testing and failure analysis facilities, staffed by dedicated engineers.

Testing Environment

T2000

V93000

AP2000e

AP3000e

Alps Alpine maintains numerous testing facilities within its factory premises.

Semiconductor Test Systems (Advantest Corporation: T7722, T2000, V93000)

These Semiconductor Test Systems inspect ASICs and SoCs for proper functionality. Our equipment includes Advantest's cutting-edge V93000 test solution and T2000, which allows for flexible module reconfiguration for various applications.

Probers (Tokyo Seimitsu Co.: UF2000, UF2000 [low-temperature compatible], and AP3000e)

These inspection systems evaluate chip quality by applying an electric current to wafer patterns and assessing their electrical characteristics. We utilize Tokyo Seimitsu's UF2000 and UF2000 (low-temperature compatible) for 200-mm wafers and AP3000e for 300-mm wafers.

Test Handler (Advantest Corporation: M4171)

This equipment enables automated temperature testing and heat generation inspections in semiconductor development. For R&D purposes, we employ Advantest's M4171, which offers various temperature tests in a compact setup.

Failure Analysis (FA) Environment

Alps Alpine maintains its own analysis equipment and employs engineers with specialized knowledge to swiftly analyze causes of failure and devise countermeasures. Our IC analysis process is comprehensive, with equipment capable of handling a wide range of analytical methods. These include visual inspections, electrical testing, non-destructive testing, the examination of failure locations after package opening, and cross-sectional diagnosis.

Our team includes experienced failure analysis engineers who can quickly identify defects caused by particles (microscopic foreign matter) generated during manufacturing, as well as faults caused by production errors. This expertise allows us to implement appropriate countermeasures promptly. Moreover, the engineers involved in the design process participate directly in the analysis, ensuring a thorough understanding of the problem's root cause and enabling the most efficient path to resolution.

Realizing a Wide Range of Customer Requirements with Our Proven Technology

Alps Alpine's ASICs have evolved alongside various sensor elements over the years, resulting in products that boast both high performance and reliability. Originally developed for in-house modules, these ASICs are now employed in diverse fields as high-quality ICs that meet international and industry standards.

We offer full turnkey services for custom product development, allowing us to flexibly address diverse customer needs, such as integrating circuits composed of discrete components into ICs. If you're considering developing products that demand advanced performance and high reliability—such as smartphones, mobile devices, automotive equipment, or gaming devices—we invite you to consult with us.