Instrumental Analytical Technologies

Instrumental Analytical Technologies of ALPS ALPINE to Support Product Development and Quality Improvement by Capturing an Item’s Nature

ALPS ALPINE is expanding its businesses to the three fields: “component”, “sensor communication” and “mobility”, which deal with 15,000 types of products. To assure the quality of these products to be incorporated into a wide variety of final products such as smartphones, home electronics and cars, we are seeking to maintain and improve our reliability by fully utilizing instrumental analyses.

Widely usable instrumental analysis

Instrumental analysis is a technology to visualize the invisible aspects of a substance by utilizing advanced analytical instruments to scientifically clarify its composition, structure and physical property. The state and property of the substance can be acquired and analyzed as objective data through an X-ray CT microscope, scanning electron microscope (SEM), Fourier transform infrared spectrophotometer (FT-IR), gas chromatograph (GC) and thermogravimetry-Differential Thermal Analyzer (TG-DTA). Instrumental analysis is a widely usable technology for material selection and performance evaluation at a stage of product development by utilizing these data to clarify the root causes of problems on products.

The Instrumental Analysis Division of ALPS ALPINE is contributing to the overall quality improvement on product development and manufacturing by providing important and fundamental technologies which support problem-solving across business any divisions such as Development, Manufacturing and Quality Assurance related to products.

The instrumental analytical technologies of ALPS ALPINE are supported not only by its lineup of analytical instruments but also its experienced analytics engineers.

Comprehensive analytical approaches

To deal with a variety of products, we are implementing comprehensive approaches by a combination of multiple analytical instruments. The most suitable instrument varies depending on the purpose such as an observational/elemental analysis, structural analysis, physical property evaluation and Environmental Compliance Substance Analysis. Therefore, there are some cases where analyses will not be completed with a single instrument but multiple instruments will be required. In such cases, we ensure analytical precision and reliability by a combination of multiple instruments to connect each analytical result for comprehensive interpretation.

In addition, appropriate preprocessing is required before each analysis. For example, advanced know-how, including cross-section preparation techniques and extraction/condensation of minor components, has been accumulated in the processes before applying analytical instruments. These preprocessing technologies are also one of the factors which have a significant influence on the analytical precision.

Extensive analytical experience and analytics engineers

Analytical technologies are not completed only with an analytical instrument. It also requires the expertise and experience of analytics engineers who precisely interpret data to draw a conclusion. The significance of analytics engineers lies in the proper interpretation of complex waveforms and numeric values acquired from analytical data to draw conclusions for problem-solving. More than 2,000 analytical achievements per year have been supported by the analytics engineers’ unique skills cultivated from experience and knowledge for more than 40 years since the Analysis Division was established.

Particularly, we value the ability to make appropriate proposals based on past problem-solving experience and brush up the analytical technologies along with the increasing complexity of products. We are contributing to both product development and quality improvement with a comprehensive enhancement in instrumental operation, data acquisition and result interpretation.

High-quality and quick response

For each instrumental analysis, we usually set the lead time for approximately 5 to 10 days as a standard. In emergency circumstances, we are prepared for immediate analyses on the arrival of samples to provide data as soon as possible.

To effectively deal with the limited resources, it is important to prioritize each analysis. We shorten the time to respond as far as possible by aligning “high-priority data” among a large amount of requested data with the Design, Manufacturing and Quality Assurance Divisions to establish an effective analytical process.

When multiple analytical instruments need to be combined together, experience and mutual communication shared with analytics engineers who have crosscutting knowledge help with providing analytical results satisfying both speed and quality.

In addition, the Analysis Division in ALPS ALPINE is expanding theme-type approaches to establish the unique analytical methods for analyses we cannot deal with by conventional methods and for problems we cannot determine on the analytical direction from a conventional point of view.

Analytical instruments to support the technologies of ALPS ALPINE (Some examples)

ALPS ALPINE owns a wide variety of analytical instruments to meet the sensitive needs from clients who request analyses.

Preprocessing technologies

-

Cross-section polisher

By processing a cross-section with polishing paper or agent, cross-section analytical preprocessing can be performed to clarify the internal and metal jointing states.

-

Ion milling device

By processing a cross-section with Ar ion beams, cross-section analytical preprocessing can be performed on multi-layer membrane and soft materials which are hard to process with a cross-section polisher.

-

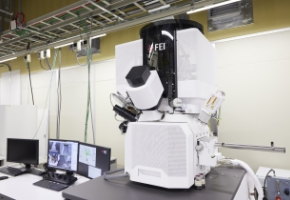

Dual beam FIB device (Dualbeam-FIB)

Compound analytical instruments which can achieve high-precision processing during observation by a combination of electron and ion beams.

Morphological observations and elemental analyses

-

Transmission electron microscope (TEM)

The internal and crystal structure can be observed at the atomic level by permeating the accelerated electron beams into a sample.

-

Auger electronic spectroscope (AES)

Elemental analyses can be performed even on samples with surface thickness in nanometers by detecting Auger electrons emitted with electron irradiation.

-

X-ray CT microscope

Makes an image of the 3D structure inside an object with non-destructive tomography by irradiating the X-ray in 360-degree rotation.

Structural analyses

-

Gas chromatography time-of-flight mass spectrometer (GC-TOFMS)

Exhaustive analyses can be performed on complex compounds with their components isolated by the gas chromatography and detected by the time-of-flight mass spectrometer at a high resolution.

-

Time-of-flight secondary ion mass spectrometer (TOF-SIMS)

The distribution of minor components can be detected at a high sensitivity through mass spectrometry of secondary ions which emit from a sample when irradiated by a primary ion beam.

-

フFourier transform infrared spectrophotometer (FT-IR)

The structure and functional groups of organic or inorganic substances can be identified with high precision by measuring the vibrational state of molecules within the absorbing spectra of infrared light.

Physical Property Evaluation

-

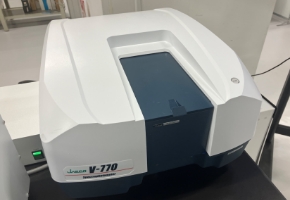

Ultraviolet-visible-near infrared spectrophotometer (UV-Vis-NIR)

Ultraviolet, visible, and near-infrared light is irradiated onto the material to measure its optical properties, including transmittance, absorbance, and reflectance.

-

Differential scanning calorimeter (DSC)

While applying a constant amount of heat, the temperature difference between the sample and the reference material is measured (heat flux type) to evaluate endothermic and exothermic reactions.

-

Nanoindenter

The hardness and elasticity in the micro region can be quantitively evaluated by a nanoscale indentation test.

Professional and crosscutting analytical structure

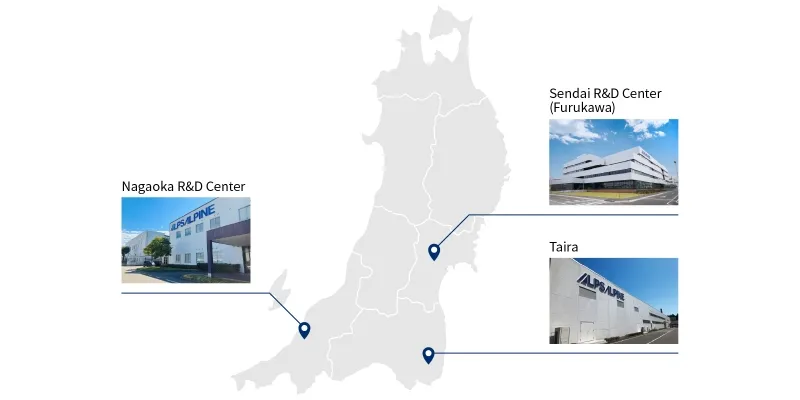

In ALPS ALPINE, instrumental analyses are being operated by three locations: Sendai R&D Center (Furukawa), Nagaoka R&D Center and Taira Plant. These locations are physically distant, but they are being operated as one department “Instrumental Analytical Technology Office” to perform analyses in close coordination.

Each location has its unique features. For example, Sendai R&D Center (Furukawa) has comprehensive analytical capabilities to cope with a wide variety of products developed by its Design Division. On the other hand, Nagaoka R&D Center is dedicated to analyses in nanometer regions to handle high-precision analyses of sensor-related products. In addition, Taira Plant is prepared for immediate response to production-related problems in a position close to the manufacturing site.

In this way, these locations effectively deal with analyses as one department by performing professional analyses which meet product properties and development needs with the strengths of each location.

Contribution to product development and quality improvement by use of analytical technologies

In 2023, Analysis Divisions in Miyagi District were consolidated into Sendai R&D Center (Furukawa) to set out an analytical technology office from scratch.

We are positioning “our analytical technologies as one of the fundamental technologies of ALPS ALPINE” and implementing approaches to directly explaining our technological capabilities and their use cases to both inside and outside of the company. To customers outside the company, we are appealing the quality assurance structure and analytical utilization at the stage of R&D in order to convey the message that “ALPS ALPINE can undertake analyses without any anxiety” for trust building. In addition, for each internal division, we are promoting further analytical technologies by presenting our specific examples to those who have not been utilizing instrumental analyses. We will keep on contributing to the product development and quality improvement of ALPS ALPINE by spreading the values and potential of analytical technologies.