Actuation Technology

Pursuing compact and highly precise movements to meet needs—actuation technology generates great excitement

“Actuation” refers to moving a machine by means such as electricity or magnetism, and the device used to perform this movement is called an “actuator.”

Alps Alpine’s actuators are primarily used in areas where extremely minute, precise motion control is required. Examples include devices that read the data of recording disks, as well as in smartphones, for the camera focus and vibration functions. Here we provide an introduction to Alps Alpine’s actuation technology, which is playing a key role behind the scenes.

The three types of actuators that Alps Alpine makes

Alps Alpine is currently researching and manufacturing three types of actuators. They are electromagnetic actuators, SMA actuators that use shape memory alloys, and piezoelectric actuators using piezoelectric elements that deform when voltage is applied.

Of the three types, the most orthodox type is the electromagnetic actuator, for which development has been progressing since around 2007. This type was developed from the technology for voice coil motors that vibrate the cones of speakers for acoustic use, and uses a small coil, through which an electric current flows, and a magnet to move the target object.

A noteworthy feature of electromagnetic actuators is that none of the components come into contact with each other, thus eliminating noise and friction while also extending the service life of the components. Since these products employ a technology that has existed for a relatively long time among the three types of methods, so they were commercialized at an early timing. At present, they are the main product in Alps Alpine’s actuator-related business.

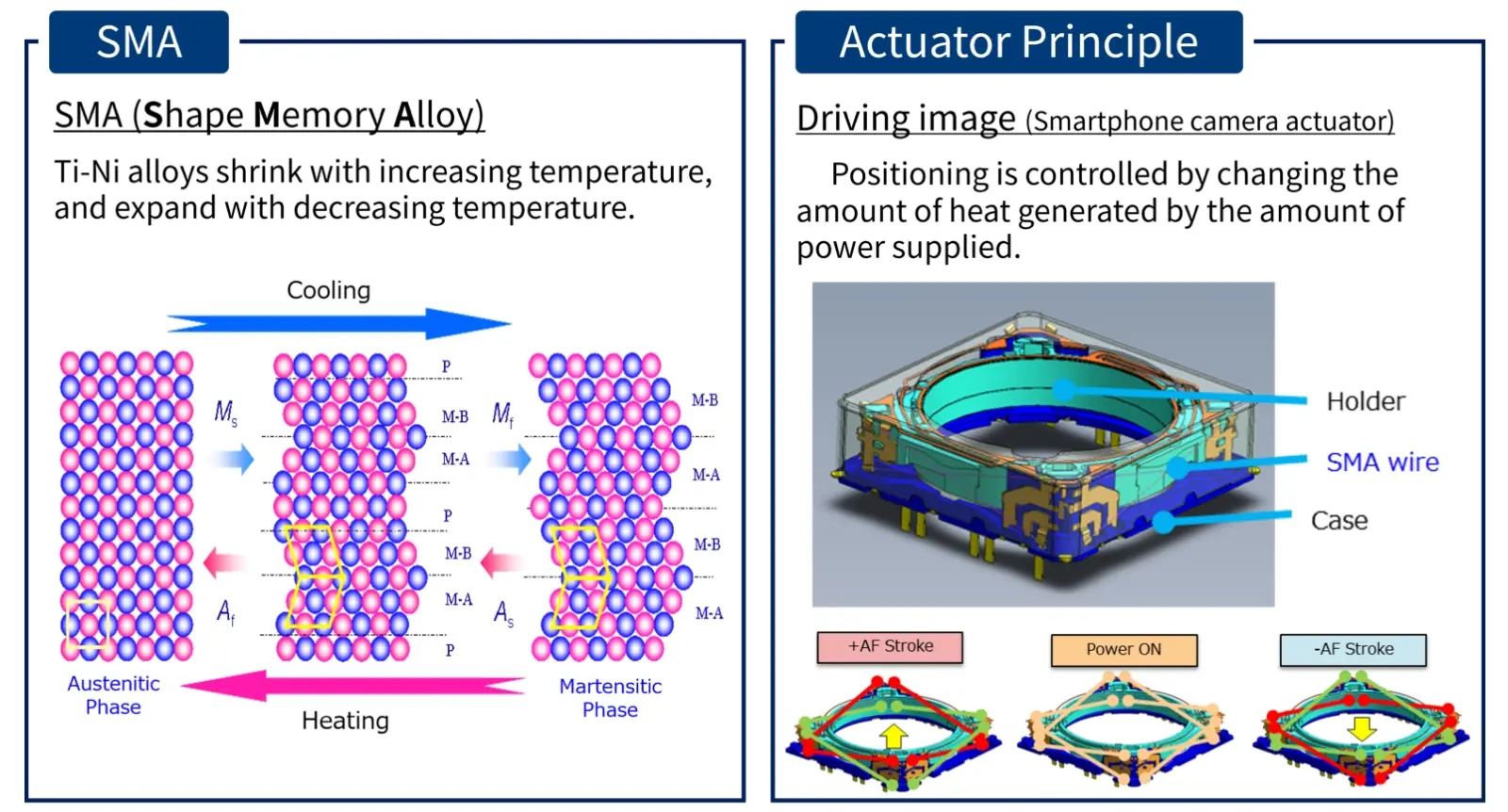

SMA-type actuators are a technology that sends an electric charge through ultra-thin wire-like shape memory alloys (SMA) that expand and contract from electricity, thereby moving the target object by expansion or contraction. The object can be moved in various directions by adjusting the direction in which the wires are laid out, or their number.

In addition, they differ from electromagnetic actuators in that they do not require a sensor for position detection. This notable feature allows them to take up less space and be lighter.

SMA actuators are a new type that was developed around 2018 and for which we have already successfully began mass production. Going forward, we anticipate that it will be applied in a wide range of fields.

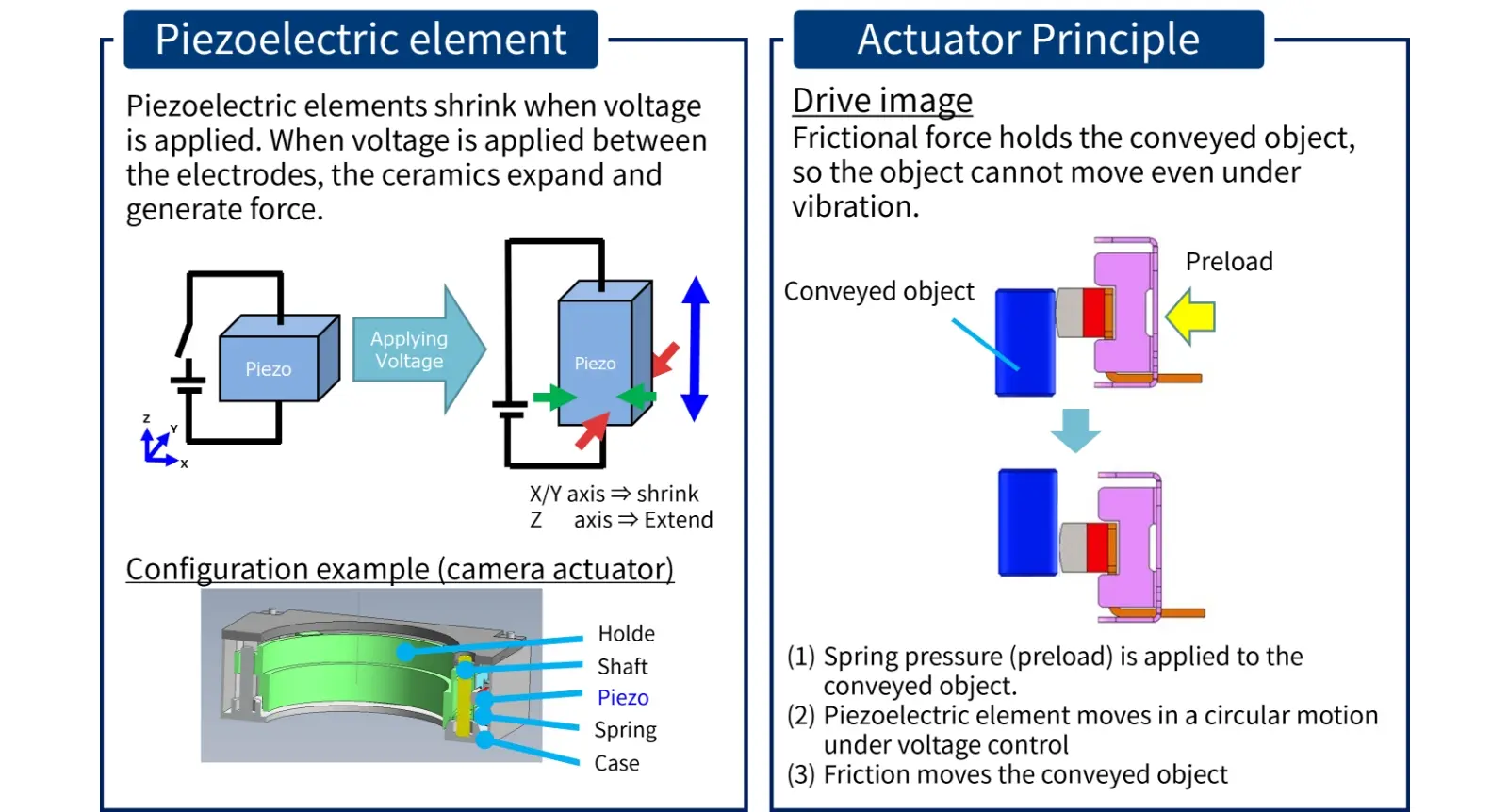

Piezoelectric actuators are another new form of actuator that has been under development since around 2018. Piezoelectric elements are one type of ceramic that, like SMA, expand and contract when electricity is run through them. While they can only expand or contract in one direction, stacking several piezoelectric elements makes it possible to create complex movements in vertical and horizontal directions. Piezoelectric actuators feature a high resistance to vibration, so they are expected to find uses in a variety of applications, such as in cameras for drones.

All three types of actuators are used in for applications that involve generating a tactile feeling, such as for adjusting the focus by moving the lens of a smartphone, or for functions that vibrate the body of the smartphone itself. It is extremely important to properly select, from among the three, the appropriate type for the specifics and size of each product.

Seeking smaller size and higher power to meet needs

In small devices such as smartphones, the internal space where components can be housed is extremely limited. As such, there is a demand for smaller components that can be more easily placed inside.

The strength of Alps Alpine’s actuators is their ability to achieve precise movements even though they are small in size. The size of our current flagship product, the electromagnetic actuator, is around 10 mm square from front to back. So that it can fit into limited spaces, it is tightly packed with a coil, a magnet, and a sensor that detects the position of the actuator.

In recent years, cameras have been achieving higher and higher resolutions. Ever more devices are being equipped with larger lenses, driving the requirement for smaller yet more powerful actuators.

In the electromagnetic type, where size is proportional to the driving force (electromagnetic force), we had to enlarge the size of the actuator itself so that it could move a large lens. However, the SMA and piezoelectric actuator types operate by physical force using wires and ceramics, respectively. As such, it is possible for them to generate more driving force than the electromagnetic type while maintaining a smaller size. We have independently developed an ultra-fine shape memory alloy (SMA) wire for the SMA type, and an actuator that conducts minute, precise movements with our piezoelectric type.

At Alps Alpine, we will continue to research methods using new materials to even better meet needs such as minimizing space, reducing weight, lowering costs, and conserving energy.

Actuation technology contributes to the evolution of a range of devices

As we move forward, we are aiming to evolve Alps Alpine’s actuators to be more energy-efficient yet more powerful. Greater energy efficiency and higher functionality in our actuators means that smartphone batteries will be able to be used for longer periods of time, and devices can be made smaller.

Going forward, we will continue to develop and offer the best actuators to match the needs of the times and of users. That is the goal of Alps Alpine’s actuation technology.