Liquid (Water) Level Sensing Using Capacitive Sensor ICs

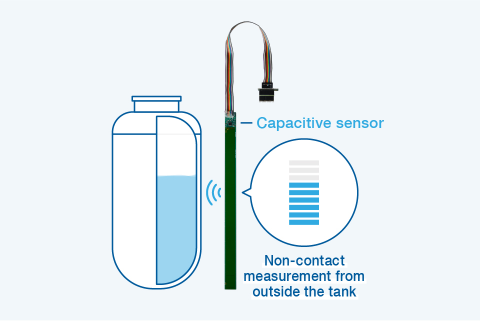

The level of liquid (water) in a container is typically detected by measuring the water level with, for example, a float inside the container. If the container is made of resin or other non-metal, capacitive technology can be used to measure the liquid level from outside the container by non-contact means.

Issue with Existing Liquid Level Sensing

There are both contact and non-contact methods of liquid level sensing. Contact methods include detecting the position of a float and measuring pressure with a pressure sensor. Both these methods have hygiene concerns about the effect on the contents—the liquid—and are restricted to certain container designs. Non-contact methods include the use of optical or ultrasonic sensors. Both these methods also have container design issues as the sensors need to be installed above the container where the liquid surface is visible.

Solution Case Example

A high-sensitivity Alps Alpine capacitive sensor IC was introduced so the water level inside a resin tank could be detected from outside the tank. Because the sensing was performed from outside the tank, water inside the tank was not affected and the tank was easily detached to refill with water.

Solution Benefits

- No effect on the contents (liquid)

-

Sensing has no impact (e.g. hygiene-wise) on the liquid contents of the container as it takes place outside the container.

- Contents (liquid) have no effect on the sensor

-

The sensor is not affected by the liquid contents of the container as sensing takes place outside the container.

- Allows a simple container structure, easy container detachment/attachment

-

Sensing takes place outside the container, allowing a simple container structure that facilitates attachment and detachment.

- Greater freedom of use of space

-

There is greater freedom in the use of space around the container as the container, a simple structure, is detected by non-contact means using a sensor beside it.