Brushed DC Motor Position and Load Current Sensing Using Current Ripple Detection ICs

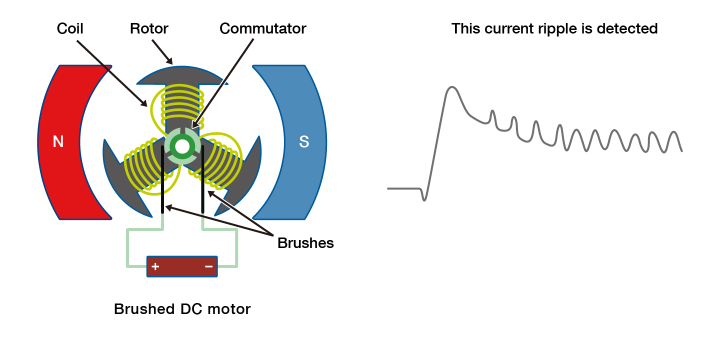

Until now, motor control has typically involved sensing the motor’s speed and angle of rotation using a magnetic sensor. If the motor is a brushed DC motor, rotation speed and rotation angle can be determined by detecting the current ripple at the brushes. Load current can be detected at the same time.

Issue with Existing Motor Control

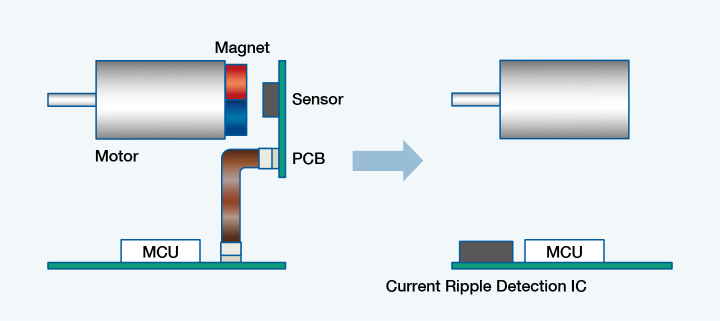

The typical method of motor control involves detecting the magnetic force of a magnet attached to the motor using a magnetic sensor.

However, this creates the following issues.

- ・It requires discrete components, such as a magnet, magnetic sensor (board-mounted), and harness, and the space for those components.

- ・The magnetic sensor needs to be located near the motor to detect the magnetic field of the magnet attached to the motor.

Solution Case Example

Because the target motor was a brushed DC motor, an Alps Alpine current ripple detection IC was employed to detect current ripple, enabling detection of rotation period, rotation speed, and number of rotations, in place of a magnetic sensor, as well as load current, in place of a current sensor.

Solution Benefits

- Fewer parts needed

-

Discrete components, such as magnetic sensors and their PC boards, cables, and magnets, can be omitted.

- Space savings

-

Having fewer parts makes it possible to achieve space efficiencies around the motor.

- Weight reductions

-

Having fewer parts makes it possible to omit cables and achieve other weight reductions.

- Layout freedom

-

The Current Ripple Detection IC helps to improve design freedom by not requiring installation near the motor. For example, it can be installed on the MCU board.