Rattling Prevention Using a TACT Switch™ with Preloading

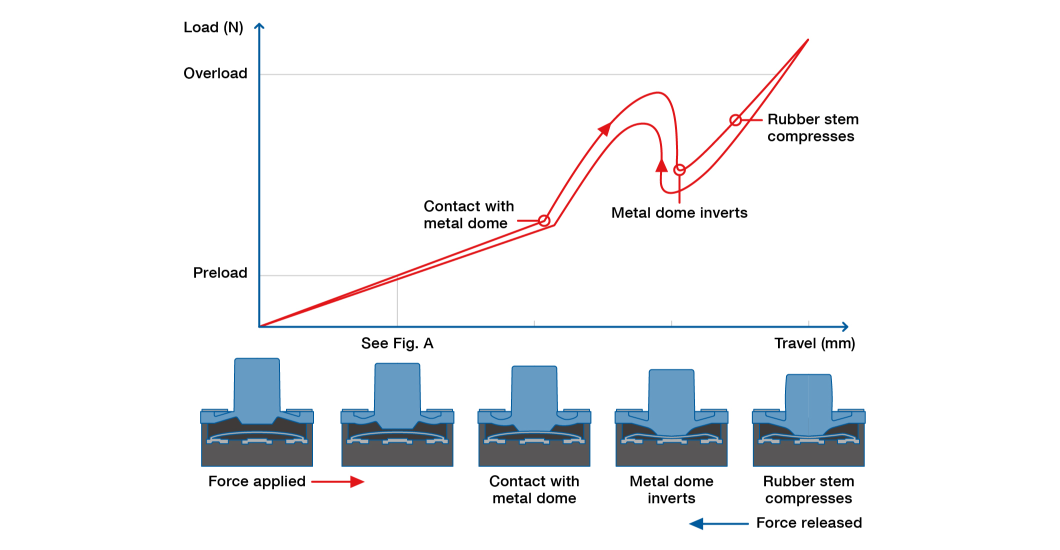

The TACT Switch™ lineup includes middle-stroke types, with a stroke (travel) roughly between 0.4 and 0.9mm. A feature of middle-stroke types is that when an elastic rubber stem is used, there is a preload prior to the moving contact being pushed, and an overload after the moving contact is fully pushed (see diagram below). The force used to push the switch influences the feel of the push.

Issue with Existing TACT Switch™ Products

In automobiles and other applications involving vibrations, any contact between parts, including TACT Switch™ products, can cause rattling. When the cabin is quiet, as is more often the case these days with the spread of electric vehicles, rattling is irritating and can even be detrimental to a brand, particularly in the case of luxury vehicles.

Solution Case Example

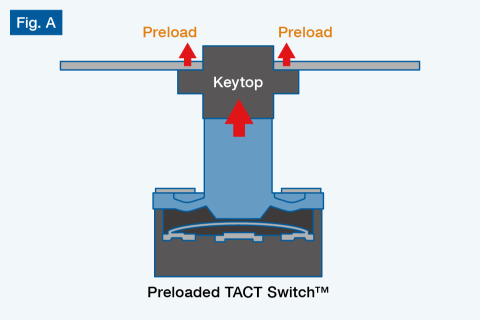

Rattling was prevented by closing the gaps between TACT Switch™, keytop and housing in advance, making active use of preloading, one of the features of Alps Alpine’s middle-stroke type TACT Switch™ models.

Solution Benefits

- Rattling prevention

-

Rattling caused, for example, by vibrations is prevented by closing the gap between the keytop and housing, with the keytop already pushed, making use of the preload.

- Adjustment of push feel

-

Preloading allows adjustment of the push feel by reducing the load applied at the start of the push.

Product Pages

-

Product Map Search

Product Map Search(Search by travel or operating force)