The life of a TACT Switch™ is seen as ending either when the number of times the switch has been operated exceeds the mechanical limit, or when the switch becomes no longer able to satisfy its original specifications due to the passing of time. In the consumer electronics sector, for example, products like home game consoles are operated a large number of times and therefore generally require switches that are durable over a high number of mechanical operations. For industrial equipment, on the other hand, switches that might not be operated much but last many years (switches with a long service life) are often sought. In this article, we introduce Alps Alpine efforts to extend the service life of TACT Switch™ products.

Usage Environments and How They Affect TACT Switch™ Service Life

TACT Switch™ parts may undergo change as a result of use over a long period. Electrical performance may be affected, too, depending on the usage environment. Changes to contact surfaces have a particularly large impact. Continuity failure sometimes occurs due to film forming on the contact surface.

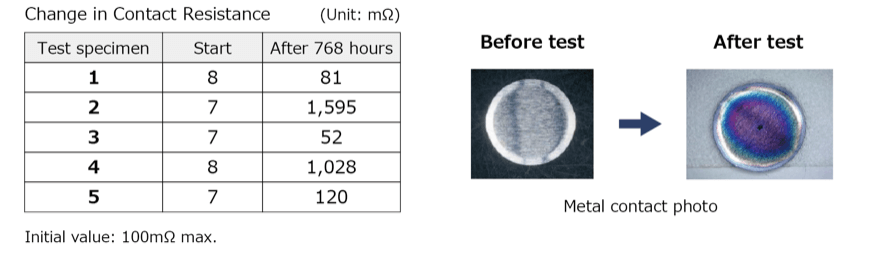

Here we will introduce the results of environmental performance evaluation testing1 of the basic SKHH Series. Evaluation was carried out using hydrogen sulfide (H2S), a corrosive gas that significantly affects silver contacts of the kind employed by Alps Alpine.

Test conditions :H2S gas concentration: 3ppm; Temperature: 40°C; Humidity: 75%; 768 hours

(Under normal environment, this corresponds to more than 10 years)

To get closer to the actual usage conditions, the switches were operated once a day.

The initial contact resistance of the SKHH Series is up to 100mΩ. After the test, there was discoloration* of the contact surface and contact resistance had increased**.

* Discoloration occurring with sulfide film formation on the surface of silver plating caused by H2S gas

** Variance in the increase in contact resistance for each specimen was due to differences in the contact state of each contact. All contacts underwent similar discoloration, suggesting diminished conductivity performance.

Almost identical results were observed in a comparison with similarly structured products of other leading Japanese manufacturers.

Prevention of Gas Ingress Around Contacts

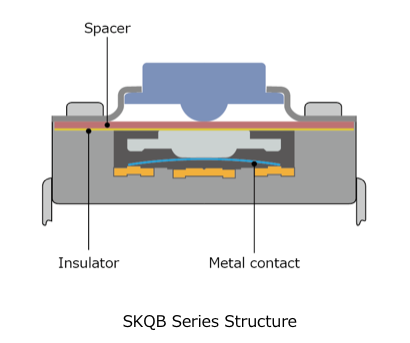

As noted above, contact degradation occurs due to the contact encountering gas in its usage environment. While the aforementioned SKHH Series does not have a sealed contact area, Alps Alpine does supply TACT Switch™ series that stop contacts from coming into contact with the outside air by surrounding them with film (insulator) and rubber sheet (spacer). Using this structure dramatically extends the service life of the contact area depending on the usage environment (e.g. gas).

The drawing on the right illustrates the sealed contact structure of Alps Alpine's SKQB Series. The metal contact is sealed using an insulator and spacer.

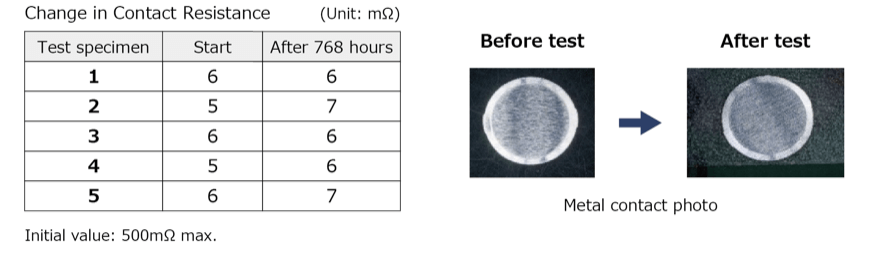

The results of environmental performance evaluation testing showed that, in contrast with the SKHH Series with unenclosed contacts above, neither contact resistance nor contact coloring changed.

Test conditions :H2S gas concentration: 3ppm; Temperature: 40°C; Humidity: 75%; 768 hours

(Under normal environment, this corresponds to more than 10 years)

To get closer to the actual usage conditions, the switches were operated once a day.

Enclosing contacts between insulator and spacer also enables prevention of the ingress of foreign substances other than gases, such as water and dust.

Here are Alps Alpine TACT Switch™ varieties that have contacts enclosed between an insulator and spacer.

Potting-Compatible TACT Switch™ Products

Potting is a sealing method that involves encapsulating an entire circuit board after mounting the components. The method allows even greater contact airtightness. Alps Alpine supplies the following potting-compatible TACT Switch™ products.

Alps Alpine also supplies other types of switch not appearing above. If you have any queries, please contact us here.