Characteristics Produced by TACT Switch™ Metal Contacts

We have previously covered the various characteristics of Alps Alpine TACT Switch™ products. One key part that creates those characteristics is the metal contact (moving contact/metal dome). Here we introduce the characteristics produced by the metal contact of a Sharp Feel Type TACT Switch™.

Operating Feel Variations Created by Metal Contacts

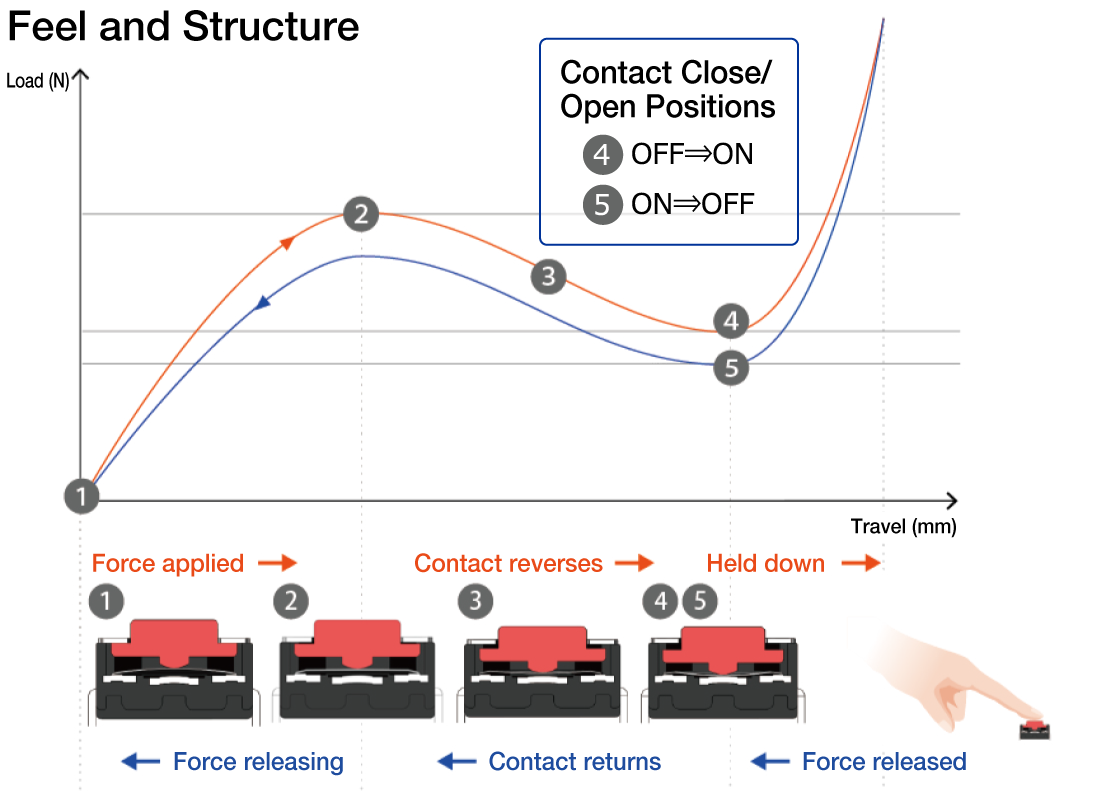

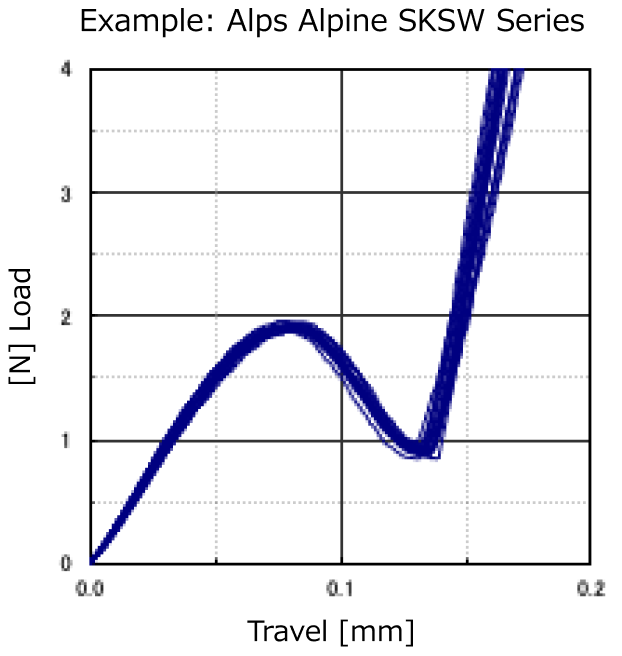

The operating feel of a TACT Switch™ can be depicted on a feeling curve showing the change in travel and load.

Read more here.

In a Sharp Feel Type TACT Switch™, travel depends on the height of the metal contact. Load varies with the thickness and dimensions of the metal contact.

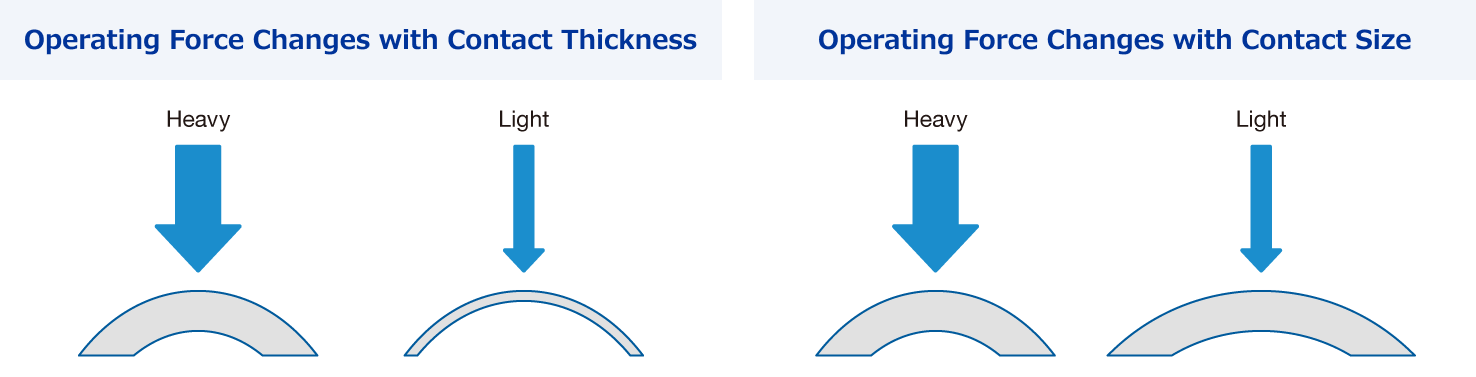

Metal Contact Thickness and Size

Load (operating force) varies with the thickness and size of the metal contact. For example, imagine a thick steel plate and a thin steel plate. More force is required to push in and bend the thick plate than the thin plate. If the steel plates are of the same thickness, a bigger plate gives way more easily, bending with a lighter force. The same applies to metal contacts. Thinner and bigger metal contacts require a lighter operating force.

So, to create the feel of a heavy operating force, a thicker metal contact should be used. If you wish for a light operating force, but with compact dimensions, you should use a thin metal contact.

Operating Life Variations Created by Metal Contacts

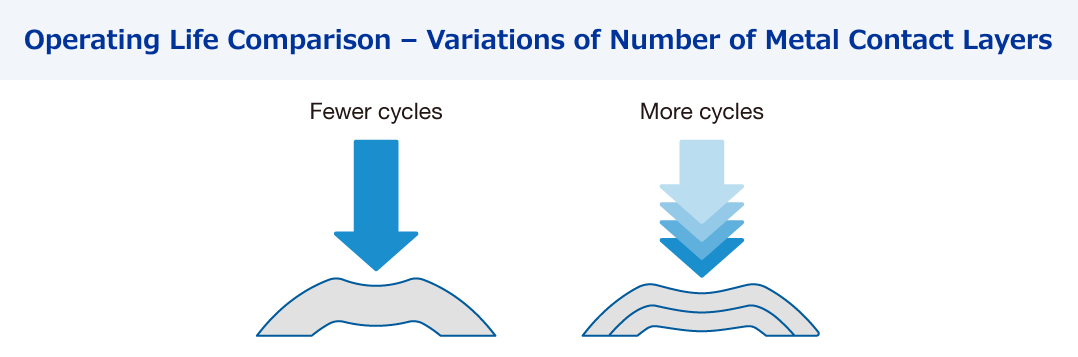

In the same way that thinner and larger steel plates are more pliable and more able to withstand repeated bending, thinner and bigger metal contacts can endure more operations. Conversely, thicker and smaller metal contacts can withstand fewer cycles.

In that case, how do we extend operating life when using metal contacts that require a heavy operating force? One way that Alps Alpine achieves this is the inclusion of models with layered metal contacts in its TACT Switch™ lineup. This method makes it possible to extend operating life even with a heavy operating force by achieving both the heavy operating force of a thick contact and the flexibility of a thin contact.

Metal Contact Material

There are currently two types of base material for TACT Switch™ metal contacts: phosphor bronze and stainless steel (SUS). Phosphor bronze has excellent strength and wear resistance and is often used as a spring material. Stainless steel is both stronger and harder than phosphor bronze and also boasts higher durability, extending operating life. This makes it possible to reduce the size and increase the operating force of metal contacts without affecting operating life. In addition, all metal contacts undergo surface treatment with silver, which has excellent conductivity.

Operating Sound Variations Created by Metal Contacts

A TACT Switch™ produces a variety of operating sounds depending on its structure, the biggest factor being the sound made when the metal contact (moving contact) hits the fixed contact. The operating sound, together with a click sensation, is feedback, conveying to the user that the operation is complete. In certain usage environments, quiet operation might be preferred. Alps Alpine works to incorporate technology for minimizing unpleasant sound and realizing quiet operation into TACT Switch™ products.

Read more here.

Metal Contact Design

TACT Switch™ metal contacts come in a variety of designs to produce the desired characteristics, such as size or feel.

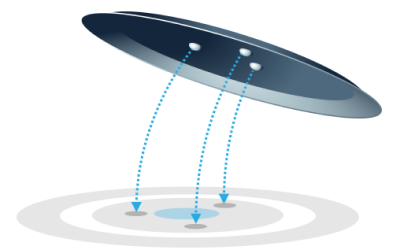

We also have metal contacts with three protuberances (dots) on the contact surface. Such contacts have excellent dust resistance. If foreign matter does get in between the contacts, there are three points that can make contact. Even if contact cannot be made at one of the points due to foreign matter getting in the way, there are still two other points that can make contact and allow current to flow.

Read more here.

Metal Contact Manufacturing Process

Variation Within Lots

In the manufacture of TACT Switch™ metal contacts, there is virtually no variation within manufacturing lots* as we carry out continuous integrated production of the same materials in-house. The chart on the right is an example showing the variation within lots on a feeling curve that indicates operating feel.

* Guarantees also covering lot-to-lot variation depend on the specifications.

Find the right Alps Alpine TACT Switch™ variety by selecting the operating force and travel.

Past articles

-

Understanding TACT Switch™ Product Specifications

April, 2025 -

Characteristics Produced by TACT Switch™ Metal Contacts

April, 2024 -

haptic reactor AFR Series / AFDU Series

March, 2024 -

Achromatic Lenses

March, 2023 -

TACT Switch™ Products with a Long Service Life

May, 2022 -

Internal Resistor Type Detector Switches

November, 2021 -

Features of Force Sensors

March, 2021 -

Air Pressure and Water Pressure Sensors

February, 2021 -

Pressure Sensors

January, 2021 -

haptic reactor AFT Series

November, 2020 -

TACT Switch™ – Realizing Quiet Operation

October, 2020 -

TACT Switch™ – Features and Effects of Middle-Stroke Types

September, 2020 -

TACT Switch™ – Middle-Stroke Types

July, 2020 -

Stick Controllers (ThumbPointer™)

May, 2020 -

Encoders

April, 2020 -

Potentiometer Varieties

March, 2020 -

Potentiometers – What Are They?

February, 2020 -

Alps Alpine's Humidity Sensors

January, 2020 -

Features of Spring Contacts

September, 2019 -

Spring Contacts – What Are They?

August, 2019 -

Features of Slide Switches

July, 2019 -

Detector Switch Varieties

July, 2019 -

A Special Feature of Detector Switches

June, 2019 -

Features of Resistive Position Sensors

April, 2019 -

Resistive Position Sensors

April, 2019 -

Angle Sensor

November, 2018 -

2-in-1 Encoder with Variable Magnetic Pole Pitch

October, 2018 -

Magnetic Sensor

September, 2018 -

TACT Switch™ as a Multifunctional Key

July, 2018 -

Factors Determining the Feel of a Switch

June, 2018 -

Having Trouble with Contamination of Electrical Contacts?

May, 2018