How to Prevent TACT Switch™ Failure – Pre-Use Checklist

Preventing Ingress of Foreign Matter

Foreign matter inside a TACT Switch™ may prevent on/off function or diminish feel

Foreign matter can get into gaps between the stem, frame, housing, and other parts of a TACT Switch™. If this interferes with the sliding of the moving part, it can cause tactile problems. If the TACT Switch™ is not a dust-resistant model and the foreign matter reaches the contact, it can cause continuity problems – the circuit will not close if the foreign matter is an insulator and will not open if the foreign matter is a conductor.

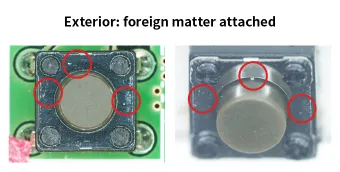

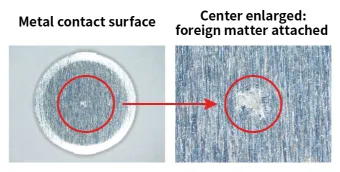

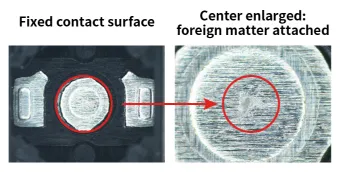

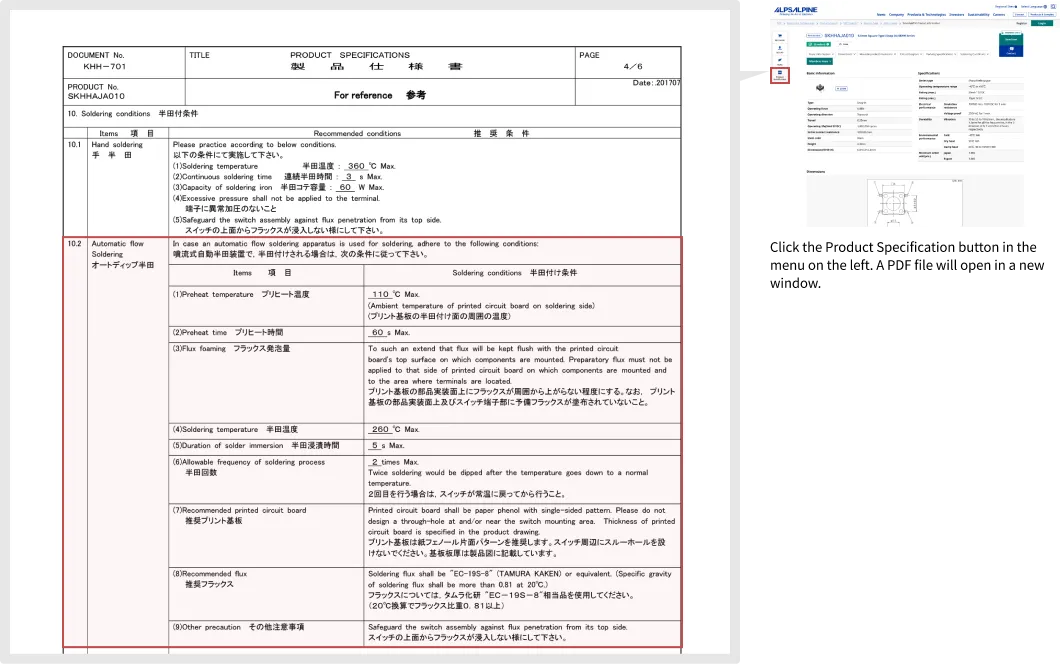

Example: SKHH Series

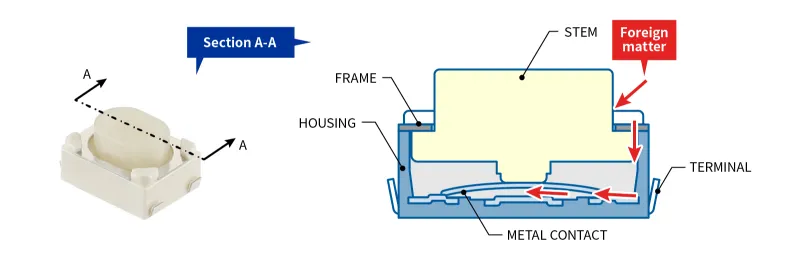

The mechanism by which foreign matter reaches the contact is as follows.

1. Foreign matter lands on the TACT Switch™. When the stem is pressed, the foreign matter enters the gap between stem and frame.

2. The metal contact rises and falls whenever the stem is pressed. As the metal contact returns, air blows the foreign matter toward the contact area.

3. The foreign matter attaches between the metal and fixed contacts.

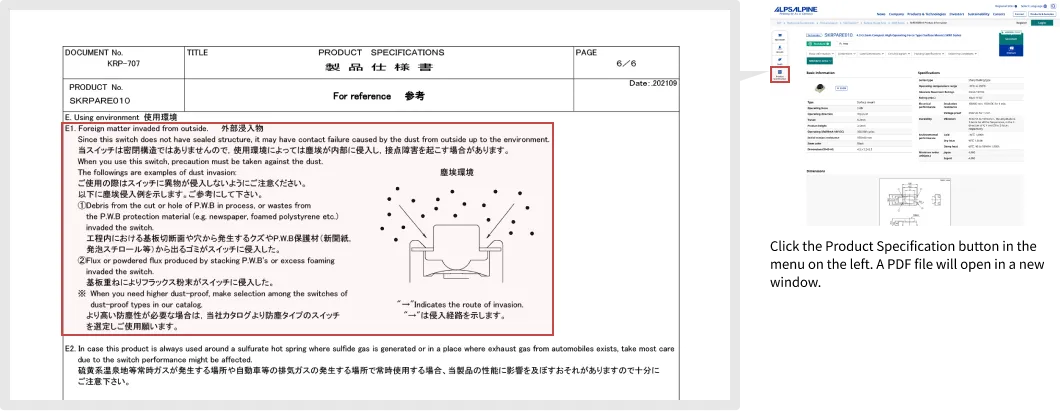

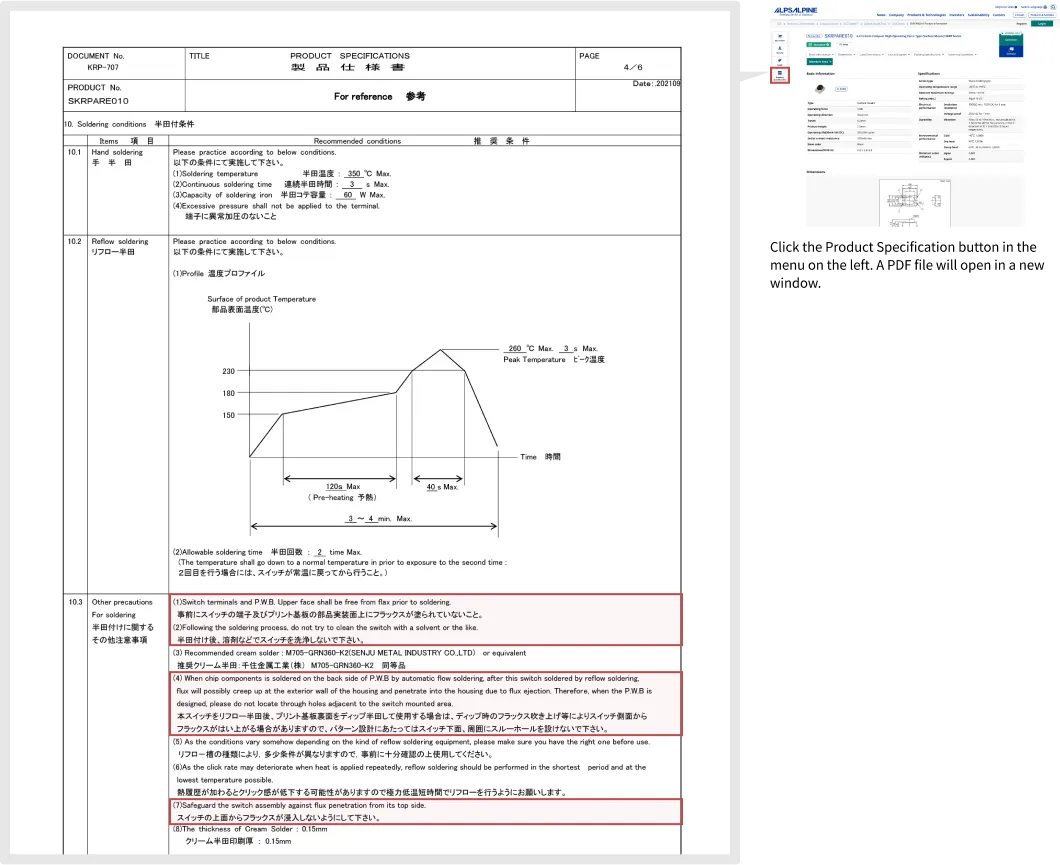

Example: SKRP Series

Countermeasures differ according to the foreign matter ingress scenario

1. Ingress of foreign matter into the TACT Switch™ of a product while the product is in use

If the product is envisaged for use in environments where there is a high likelihood of foreign matter ingress, consider using one of our dust-resistant TACT Switch™ models.

2. Ingress of circuit board debris when dividing TACT Switch™-mounted circuit boards

Circuit board debris created when dividing circuit boards to which a TACT Switch™ has been mounted may make its way inside a TACT Switch™. When dividing circuit boards, take steps to ensure that board debris does not remain on the board. For example, use a dust collector.

- Checking the Specifications

-

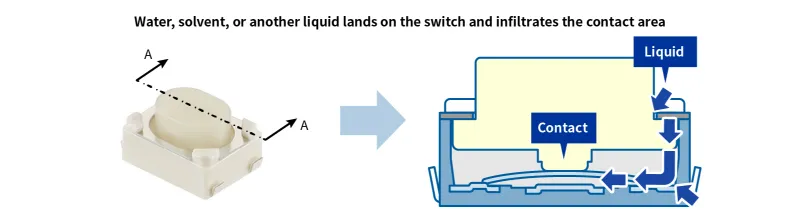

Preventing Intrusion by Water or Other Liquids

Water or another liquid inside a TACT Switch™ may prevent on/off function

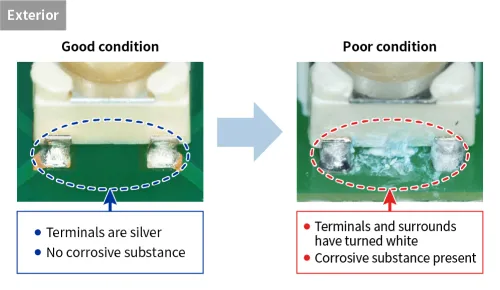

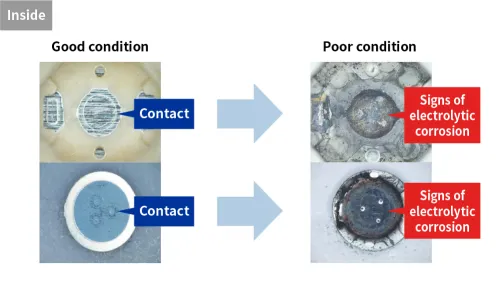

Water, solvent, flux, coating agent, or another liquid inside a TACT Switch™ that is not a water-resistant model may lead to corrosion (electrolytic corrosion) of the contact, causing the circuit to either not close or not open.

Example: SKRP Series

Actual Failure Examples

Countermeasures differ according to the liquid intrusion scenario

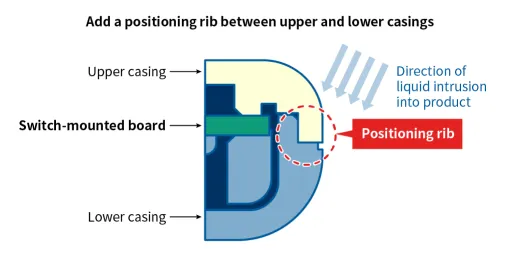

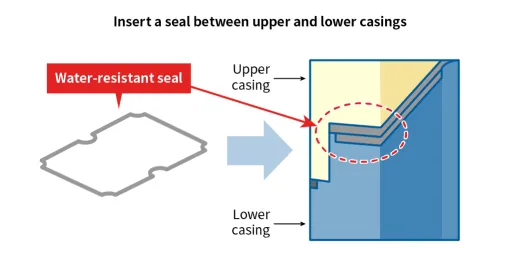

1. Liquid intrusion from outside the enclosure of your product

Explore options for preventing liquid intrusion, such as changing the enclosure design or using a water-resistant seal.

Or…consider using one of our water-resistant TACT Switch™ models.

2. Liquid intrusion during manufacturing of the mounting board for the TACT Switch™

- Intrusion during the washing process

-

With the exception of some series, please refrain from washing mounting boards

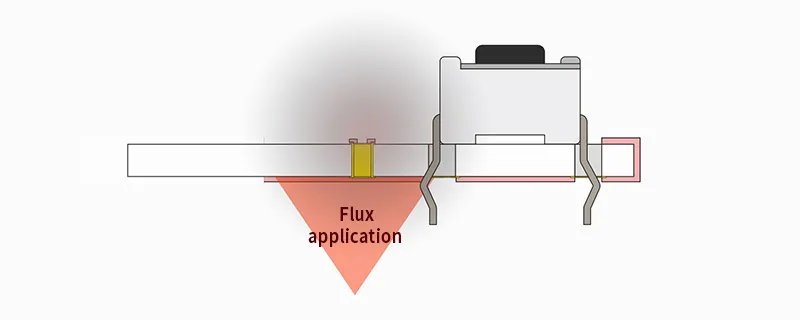

- Intrusion during the dip soldering process

-

Flux applied prior to soldering can sometimes infiltrate the TACT Switch™; for example, via through-holes. Please adhere to the TACT Switch™ mounting hole dimensions and position the switch away from through-holes not used for switch mounting and from board ends. Also make sure to adhere to conditions for auto dip soldering in the Product Specifications.

- Intrusion during the reflow soldering process

-

Flux in cream solder can sometimes infiltrate the TACT Switch™ during the reflow process. Before mounting, check soldering cautions in the Production Specifications.

- Intrusion during application of coating agent

-

Inquire with Alps Alpine prior to using a coating agent. Do not use adhesives or coating agents that produce corrosive gas, or that are of low viscosity and may seep inside the switch. Before use, also check, using an actual model, that the required adhesive strength and water resistance is achieved.

CAUTION

Please note with the SKRA Series and other TACT Switch™ models that employ rubber materials, if a substance like grease attaches to the rubber material, the rubber may expand and cause the switch to malfunction even when the substance does not infiltrate the inside of the TACT Switch™.

- Checking the Specifications

-

- Also check the following cautions of use.

-

B. Soldering and assemble to P. W. Board process (B4)

C. Washing process (C1)

D. Mechanism design (D2)

E. Using environment (E1 Foreign matter invaded from outside (2), and E3)

Preventing Failure Due to Abnormal External Force

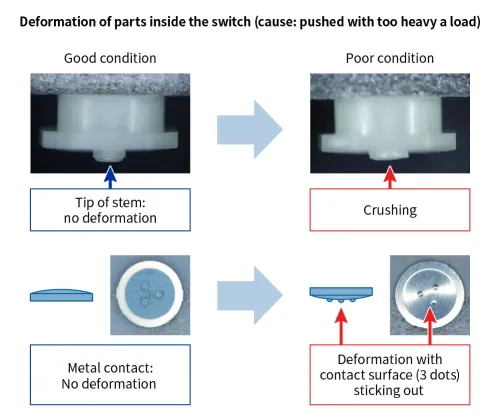

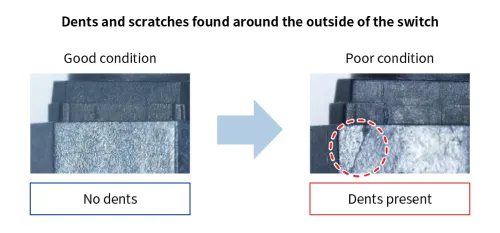

An abnormal force applied to a TACT Switch™ from the outside may prevent on/off function or diminish feel

If a TACT Switch™ is operated with strong force or subjected to the load of an impact, such as by being dropped, it might cause on/off function defects or tactile problems.

Example: SKRP Series

Example: SKPM Series

Do not reassemble for reuse a TACT Switch™ that has come apart after being subjected to an abnormal external force.

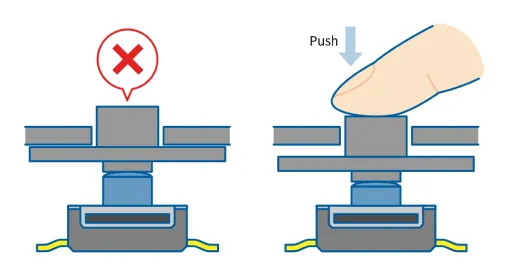

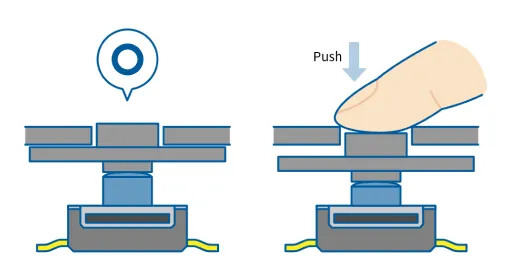

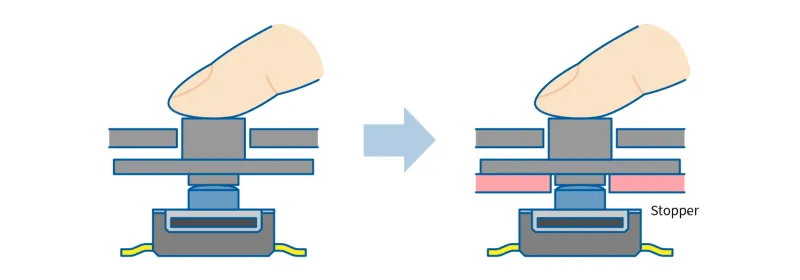

Countermeasures differ according to the abnormal external force scenario

1. Dropping of the product or application of an abnormal external force during use

Design the end product so that when the switch is pushed in, the tip of the key top sinks below the external surface of the product.

Or insert a stopper on the end product side so the TACT Switch™ is not subjected to a direct impact.

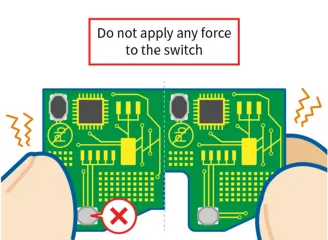

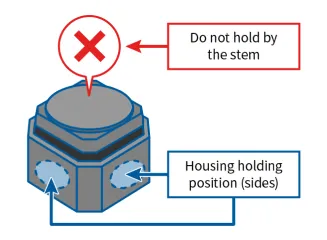

2. Application of an abnormal external force during handling of the circuit board with mounted TACT Switch™

- Checking the Specifications

-

- Also check the following cautions of use.

- B. Soldering and assemble to P. W. Board process (B3)

- SKSUBCE010 Specifications

-

D. Mechanism design (D10 and D12)

Please check specifications for each model as item numbers differ for other models.