TACT Switch™ Mechanical Design Technology

Controls on equipment and devices often require a physical operation like pushing or turning, the feel of which is determined by mechanical design technology embodied in their components. Alps Alpine has worked ceaselessly to refine its mechanical design expertise and the fruit of those endeavors comes through in our TACT Switch™ products. These switches with compact dimensions as small as 2.6 × 1.6mm contain technology and know-how that enable flexible creation of push feel.

What is a TACT Switch™?

A TACT Switch™ is a push-button switch that delivers distinct tactile feedback (click feel) when operated. As a human-machine interface for consumer electronics, automotive systems, industrial electrical equipment and other products, there are many different applications.

World Top-Class Share with Annual Production of 5 Billion Units

TACT Switch™ production began in 1976. First applied in home appliances and audio-visual equipment, use spread in recognition of their operability and convenience and they are now found in products like automobiles and smartphones. More than 155 billion have been produced to date. Alps Alpine produces around 5 billion units each year, which computes to approximately 160 per second. We enjoy a world top-class share for this type of switch in a packed market, supplying over 2,000 customers.

Despite the switches having only between three and seven basic parts, Alps Alpine has devised all kinds of ways to enhance performance and quality and has established a product lineup with broad variety. Besides models with compact, thin designs, in recent years we have developed products satisfying IP67/68 dust and water resistance* standards as demanded for products like smartphones and wearable electronics.

*See “Product Basics” for a more detail on dust and water resistance.

Internal Structure and Feel

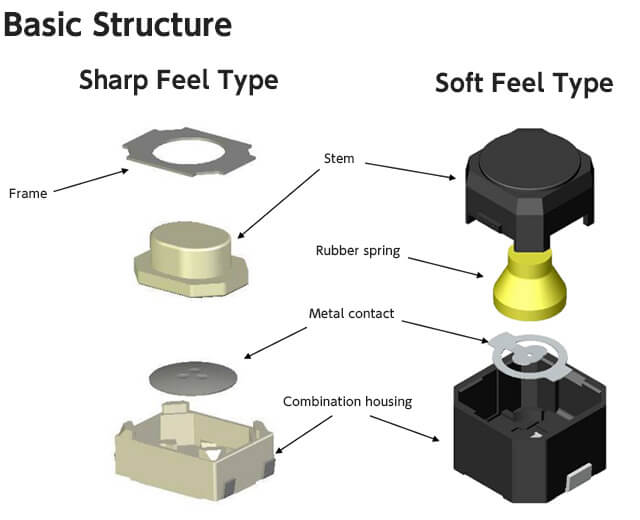

TACT Switch™ products with a metal dome provide a sharp push feel, while those with a rubber dome give a soft push feel. The required operating force (strength of push) and travel of a TACT Switch™ depends on where it will be installed and what it will be used for. Although the structure is very simple – the circuit closes when a metal contact moves vertically to touch a fixed contact – the feel produced varies with the particular shape and material combination of the components. In addition to the functional value of transmitting a signal, such as “on” or “off,” Alps Alpine believes such feel creation adds to the value of the end product and therefore strives to develop the technology further.

Delivering the Desired Feel

Alps Alpine’s TACT Switch™ lineup provides tremendous variety, offering more than 1,000 different kinds so that customers can select a model with specifications suited to their needs. If a customer is looking for a new type of push feel not yet available, we can design a new model based on the desired characteristics (tactile feel and sound), operating life (durability) and size.

The most important elements – the characteristics – can be depicted as an F-S curve. With load (force) on the vertical axis and travel (stroke) along the horizontal axis, it is possible to check parameters that determine the feel of a switch, such as operating force, return force and click ratio. We then employ material processing technology, precision processing of molds and dies, simulation technology and rigorous testing using feel measurement instruments and other equipment to actually create the desired push feel. With overwhelming product variety and the design and development capabilities to realize a particular feel, we provide customers the products most suitable for them.

A Database of Know-how

As a visualization of feeling, F-S curves provide major benefits not only for customers we deal with directly but also for switch development as a whole. Alps Alpine has been creating a database of design and development know-how based on F-S curves since around 20 years ago. Previously, seasoned designers would pursue a cut-and-try approach involving the manufacture of prototypes based on rule of thumb. It then became possible to carry out design by quantitative, logical means, leading to dramatic improvements in feel creation accuracy and quality. Having compiled a database of knowledge and know-how stored inside the minds of designers, it is possible, after advanced analysis, to simulate models on a computer prior to manufacturing a prototype. Not only does this improve the quality of the completed prototype, it also reduces the time and money expended on work and enables provision of a smooth, meticulous service to the customer.

Push Feel and Brand Image

Demand for HMI device feel development has grown in recent years and characteristics like tactile feel and sound are again looked to as a way to differentiate a brand. Humans are able to perceive subtle differences in feel with their fingertips and when they push a switch, they experience sensations such as pleasantness, smoothness, satisfaction, luxury and reassurance.

Besides storing know-how on feel creation, Alps Alpine also teams up with universities to pursue an engineering approach to research and carry out demonstration testing. TACT Switch™ products are touched and operated by people as devices that appeal to their sensitivities. As such, their push feel can sometimes influence a product’s, or the company’s, image. Alps Alpine will keep working on product development to generate the feel that customers want and uphold the brand image.

Efforts made in the area of feel creation, plus relentless activities to improve durability and reliability have brought to life a powerful TACT Switch™ lineup. Consistent quality and stable supply are achieved by manufacturing all products using automatic machines developed in-house, with a great deal of thought going into the assembly process. We go to all lengths to enhance operations from design and development through to the production setup in order to be able to satisfy the needs of customers.