Senclear™

Microfluidic Devices with High-Performance Resin Bonding

Alps Alpine’s microfluidic devices are made from high-performance engineering resins cyclo-olefin polymer (COP) and cyclo-olefin copolymer (COC). As high-performance plastics with properties comparable to glass, COP and COC are also employed in lenses and other optical components. They are ideal materials for microfluidic devices, with many advantages including low autofluorescence, excellent transmittance, low protein adsorption, high strength, disposability and high mass production viability. Bonding, however, posed difficulties given the hydrophobic nature of the molded surface and industry players struggled to overcome them. Alps Alpine’s answer was to develop its very own original bonding method.

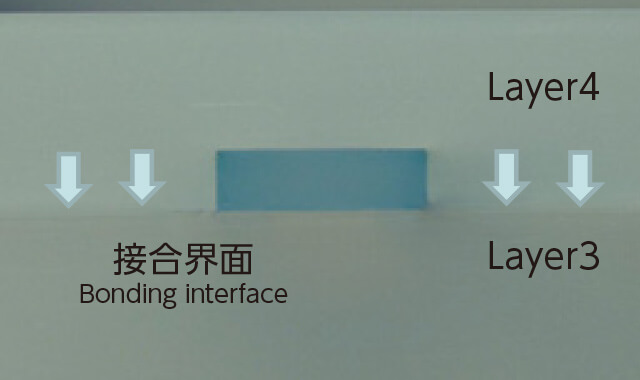

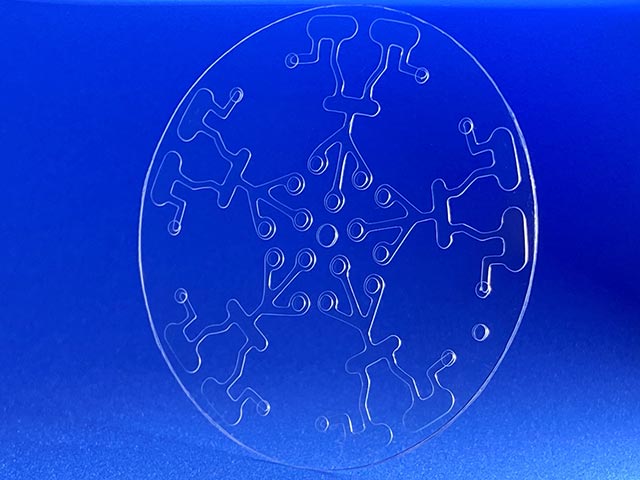

Microfluidics plate bonded using original technology

Channel cross-section

Bonding of up to seven COC or COP plates is possible at any one time using this technique, the main feature being the realization of high bonding strength and pressure resistance without using an adhesive. If an adhesive or double-sided tape were used and even just a tiny portion of its constituents separated and found its way into a specimen, toxicity and other factors would make an accurate measurement unobtainable. Alps Alpine devices bonded without adhesive are integrally joined, as if they were machined that way, so contamination by extracted substances is not a concern.

Micron-level precision is maintained using advanced mold technology while outstanding bonding strength and integration at the casing failure level is enabled with the ability to withstand 10MPa internal pressure ensuring plates do not come unstuck from the bonding surface. The devices therefore function properly as completely closed devices that do not come unstuck, break or leak when carrying specimens like blood, upholding reliability in testing and analysis. Applying original techniques specializing in the use of excellent COP and COC materials, Alps Alpine was able to establish an industry-first solution.

Senclear™: Finding Use in Drug Discovery and Development and Innovative Medicine

Alps Alpine’s Senclear™ microfluidic devices enable configuration of 3D microfluidic structures using channel designs suited to each application and stacking of plates without adhesive. Processes to choose from, depending on the need, include mixing, synthesis, reaction, purification, separation, isolation, dispensing, extraction, concentration, amplification, dilution and detection.

Senclear™ increases the speed and efficiency of testing and analysis. In the field of drug discovery, where considerable time and money is invested during the process from research and development to clinical trials and approval, Senclear™ helps to dramatically speed up and reduce the cost of translational research. Applications are also expected in innovative domains, such as regenerative medicine, involving iPS cells, and biopharmaceuticals.

Senclear™ multilayer microfluidic device structure

The Ever-Evolving Senclear™ Series

Alps Alpine’s Senclear™ microfluidic devices are constantly evolving to satisfy the huge variation of customer requirements. Certified FDA grade robust bonding and observation at high magnification, distortion-less bonding using film allowing high heat transfer efficiency, and the realization of ultra-thin channels between bonded film layers…extensive design freedom allows the creation of ideal forms to match the usage scenario.

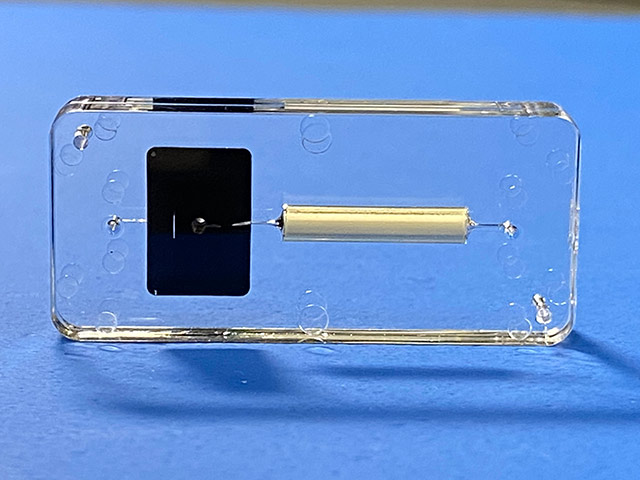

Bonding without adhesive or double-sided tape has also enabled technology for building components such as photocells and membrane filters into microfluidic devices. This makes it possible to perform testing, separation and analysis with just small samples and little reagent, enabling smaller measuring equipment and faster testing. It is hoped devices will be deployed in various test kits.

New technologies basking in the spotlight right now are organs-on-chips and other microphysiological systems (MPS) and attention has turned to microfluidic devices as completely closed systems for realizing them. In pharmaceutical research, in particular, prior to clinical trials, drug discovery targets need to be found and subjected to experiments with living bodies. Specimens used for biological experiments have conventionally been cells or tissue of laboratory animals like mice or monkeys, or even whole animals. This experiment process demands an enormous workload and time. There is also a growing need, from an animal welfare and ethical standpoint, for techniques to replace the use of laboratory animals. MPS devices are a characteristic type of chip with chambers required for cell culture and microfluidic channels for circulating the culture medium. The likelihood of MPS devices replacing laboratory animals is high and enabling the technology is expected to contribute to SDG efforts and dramatic cost and time reductions.

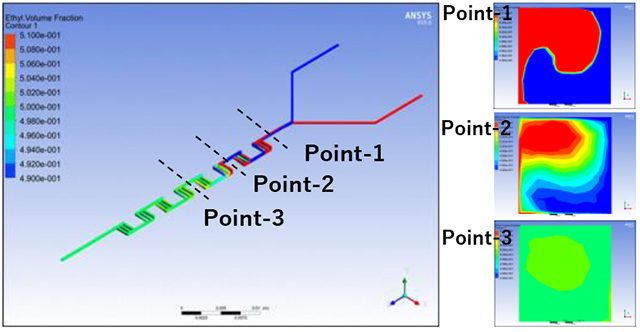

Microfluidic device for mixing two liquids

(Dimensions: 30×70×t2mm; material: ZEONOR® 1020R)

Fluid simulation

Device for cell culture/observation

(Dimensions: 15×15×t4.1mm; material: ZEONEX® 690R)

Cross-section

Microfluidic device for back-forth flow between two (upper/lower) temperature zones

(Dimensions: 26×76×t4.4mm)

Structure

Microfluidic device as film

Microfluidic device with built-in optical cell/column

Latest Deployment of COP/COC Bonding Technology

COP and COC bonding technology has hidden potential for realizing forms unachievable with metal molds, making use of high bonding reliability and design freedom. New optical components with seamless integral forms are enabled without relinquishing the superior optical properties of the COP or COC. There are also hopes for application of a low dielectric constant and low dissipation factor to new electronic components with superior high frequency characteristics. Our original COP and COC bonding technology will continue to evolve in diverse areas.